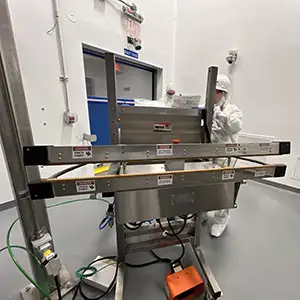

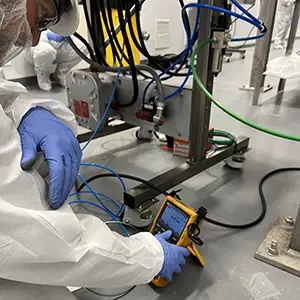

On-Site Installation

IMPAK provides a variety of sealing machines, from tabletop impulse sealers to double chamber vacuum sealers to advanced explosion-proof sealers for use in hazardous environments. Most of these can be installed and operated by users with little to no instruction from us. But the more complex a machine is, the higher the risk of equipment malfunction, damage to facility infrastructure, or operator injury.

IMPAK commonly performs Factory Acceptance Testing (FAT) in our production facilities to verify that equipment is built and operating according to design specifications and customer requirements, and documentation thereof is provided to the customer. Many customers, including those who have experience with heat and vacuum sealing equipment, are able to handle installation based on information provided by the FAT. There are, however, situations in which on-site installation support is crucial, such as:

- Confirming electrical power is adequate for safe operation

- Confirming compressed air setup is adequate for safe operation

- Confirming the physical space in which the equipment will be used is adequate for safe operation

- Providing instruction for optimal and safe operation of the equipment

Ask us about on-site installation services and explosion-proof sealers for hazardous environments.

IMPAK technicians provide installation and operational instruction support for sealing equipment delivered to a global healthcare provider