Desiccants

What are desiccants?

Desiccants are a type of sorbent that will remove moisture and water vapor from the surrounding environment, in many cases a MylarFoil bag, tin, drum, glass or another type of sealed enclosure; the combination of a sealed container with a desiccant or oxygen absorber is sometimes referred to as active packaging or a sorbent system. Desiccant media are a very hygroscopic, sometimes natural solids that are chemically inert. They trap water vapor molecules in tiny pores or tunnels, preventing them from escaping and thereby keeping products dry.

Types of desiccants that IMPAK Corporation carries include: indicating molecular sieve and non-indicating molecular sieve in a range of pore sizes (3A, 4A, 5A, and 10A or 13X). Plain white silica gel, blue indicating silica gel, and orange indicating silica gel; montmorillonite clay; activated alumina; activated carbon; calcium oxide and calcium chloride. The type of desiccant that a technical representative will recommend is going to vary by customer-specific applications and requirements. For more information:

When evaluating and discussing desiccants, it is important to keep the following in mind: What type of package are you attempting to desiccate? If you are using a pouch that has a high water vapor transmission rate (WVTR) you may want to increase the amount of desiccant used to accommodate the higher amount of water vapor that will be transmitted through the film over the course of the package's lifetime. What is the volume of the area you are working with? If you have a large amount of interstitial space (amount of space between the product being packaged) or a lot of headroom (amount of space between the top of the product and the top, sealed area of the container) you may want to increase the amount of desiccant to compensate for the increased volume. How long do you plan on the product being packaged? When a long shelf life is desired you need to take into consideration the type of container again and calculate the amount of water vapor that will be transmitted through the container wall (if any) and adjust accordingly. Is this product going to be consumed? If so, you may want to evaluate a clay or non-indicating silica gel desiccant for products such as these. Do you want to be able to re-use the desiccant after it is saturated and can no longer adsorb moisture? If so, you may want to evaluate clay and silica gel. Both desiccants are able to be regenerated in an oven when in their bulk form - do not attempt to dry/bake desiccant pouches! We also carry a 5lb (80 unit) clay desiccant bag that can be placed in an oven.

About Desiccant Units Why Molecular Sieve Is the Best Desiccant

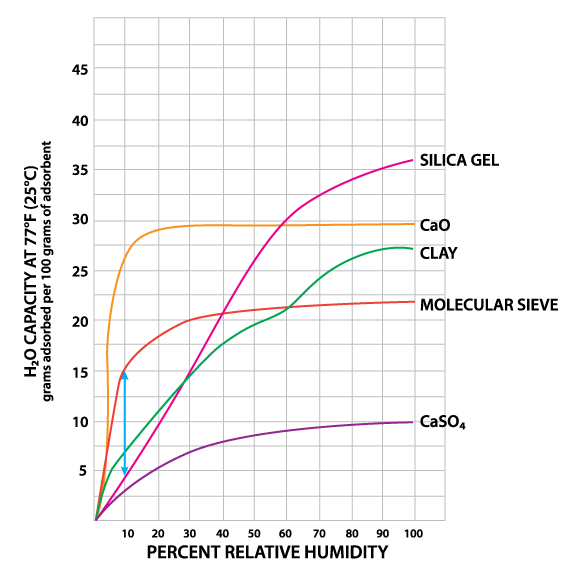

Water Capacity of Various Sorbents at Different Relative Humidity Levels

This graph clearly demonstrates the key factors in making a decision on which sorbent is most appropriate for a number of applications. By way of example, this is a graph that clearly shows how both calcium oxide and molecular sieve have some of the highest capacities at low relative humidity levels.

If your target relative humidity for your product i.e. a lateral flow device, a printed circuit board, a sophisticated piece of electronic equipment, is less than 10%, then this graph clearly shows that with molecular sieve you are getting more than twice the “product” on a gram for gram basis than you are with silica gel. As an industry leader in providing the full range in sorbents, we know how important it is to understand your particular application and how critical it is to answer the question.

”What relative humidity do we want our product not to see?”

“What level of relative humidity should we ensure that our product never sees?”

- All About Desiccants

- Anti-Fog Camera Silica Gel Paper

- MoisturePak™ 62% Humidity Control

- Bulk Desiccants

- Caps and Vials

- Cargo Container Desiccant

- Compression Molded

- Desiccant Bags

- Desiccant Packets

- Desiccant Paper

- DriBox™ - Reusable Moisture Control

- High Temperature Desiccant

- Humidity Indicator Cards

- Liquid Absorbers