Tube Sealing - Turning A Leak Into An Opportunity

For an up and coming electronic cigarette liquid salt noicotine company, having a leak can case more than just some messy hands. Direct contact with skin can cause serious health risks if not careful. Tired of always finding small leakers, this E-Liquid company contacted us to see if there was a better way.

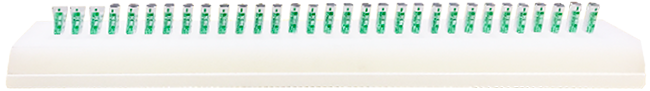

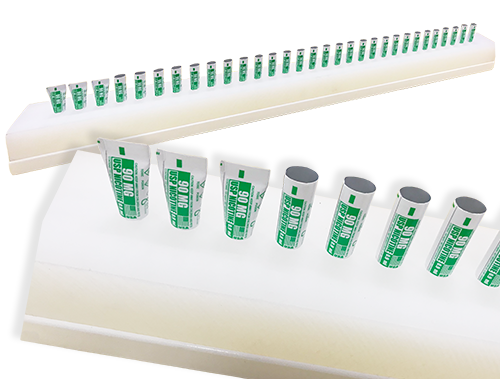

The original intent was to use flexible film pouches to budle sets of tubes without risk of any leaks extending past that batch. While we help them design and produce custom packaging for that, we were able to give our opinions on how to optimize their tube sealing operation. Perhapse unsurprisingly, the biggest improvement we could recommend was to upgrade to a more professional sealer. The unit they had was not only low throughput, but was not able to get a consistant seal. We worked with them to provide one of our MSTSS760 paired with custom tube racks to make the process far faster. Within a few months they were able to ramp up production, confident that the leaks that had been plaguing theme were not going to be an issue. Having the right equipment helped them to expand and devlop their business with the knowledge that their product is arriving as intended.