What is "Clean Room Ready"?

"Clean room ready" refers to the state of being suitable for use in a clean room environment without introducing contamination. Clean rooms are controlled environments designed to maintain high levels of cleanliness by minimizing particulate matter, impurities, and pollutants.

Clean Room Standards

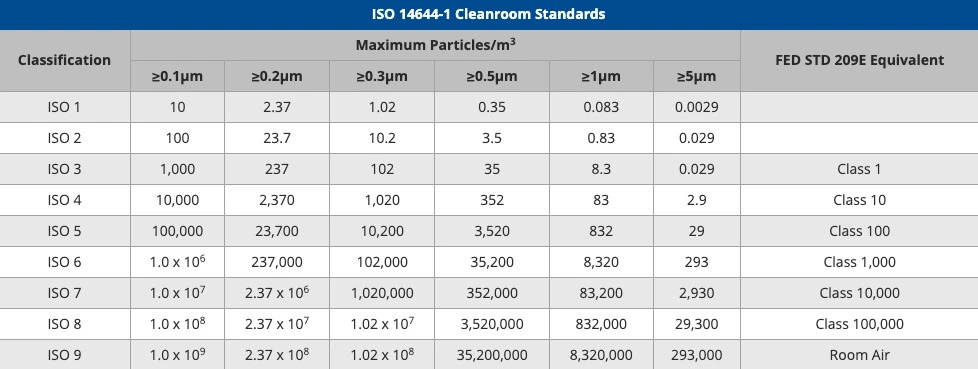

Clean rooms are classified based on the maximum allowable particle count in a given volume of air. Common clean room standards include:

- - ISO classes (ISO 14644-1)

- - Federal Standard 209E (FS 209E)

Requirements for "Clean Room Ready" Status

To achieve "clean room ready" status, equipment, tools, garments, or materials must undergo stringent cleaning, sterilization, or manufacturing processes. This ensures that they do not compromise the controlled environment of the clean room.

Variation in Definition

The precise definition of "clean room ready" may vary depending on the specific industry and clean room standard being followed. Each industry may have its own set of requirements and guidelines for achieving clean room readiness.

What is Class 100 Clean Room?

Class 100 clean rooms are controlled environments designed to maintain a very high level of cleanliness. They are classified according to the number of particles allowed per cubic meter for particles of 0.5 micrometers and larger.

For Class 100 clean rooms, the maximum allowable particle count is 100 particles per cubic meter (particles/m³) for particles of 0.5 micrometers and larger.

These clean rooms are used in industries such as semiconductor manufacturing, pharmaceuticals, and biotechnology, where strict control of particulate contamination is crucial to ensure product quality and process integrity.

Importance of Class 100 Clean Rooms

Class 100 clean rooms play a critical role in industries that require precision manufacturing and handling of sensitive materials.

Key reasons for their importance include:

- Minimizing particle contamination that could negatively impact product performance.

- Ensuring compliance with industry standards and regulations.

- Protecting workers and products from potentially harmful pollutants.

- Enhancing research, development, and manufacturing processes by maintaining a controlled environment.

Other Clean Room Classes

In addition to Class 100 clean rooms, ISO 14644-1 defines various other clean room classes, each with specific particle count limits for different particle size ranges.

Some examples include:

- ISO Class 5: Maximum 3,520 particles/m³ for particles ≥ 0.5 micrometers

- ISO Class 6: Maximum 35,200 particles/m³ for particles ≥ 0.5 micrometers

- ISO Class 7: Maximum 352,000 particles/m³ for particles ≥ 0.5 micrometers

- ISO Class 8: Maximum 3,520,000 particles/m³ for particles ≥ 0.5 micrometers