Testing Product Moisture Sensitivity

How to tell if your product is sensitive to moisture?

IMPAK Moisture Testing Services

"We ARE Biotech Support"

- Test with us for $525*

* Comparable labs charge over $1500

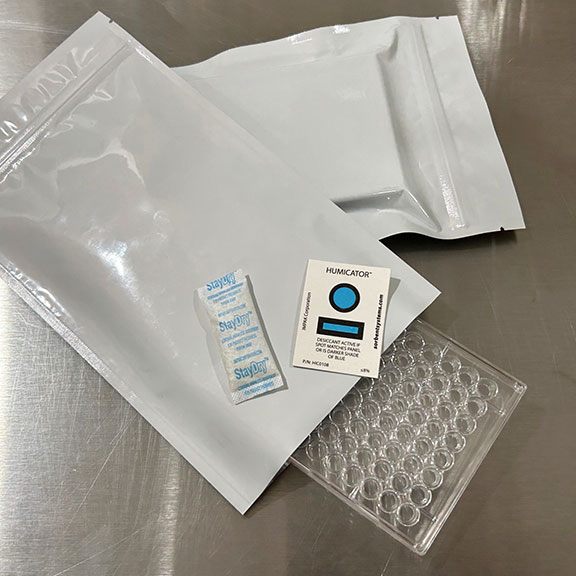

Not sure about how to tell what Relative Humidity (RH) you need to avoid? Contact IMPAK about our new Relative Humidity testing service today. Give us your product, complete with your packaging and desiccant(s) of choice. We will monitor your actual in-package environment through real-world cross-country shipping to map moisture levels while traveling. This provides a sense of the standard shipping environment the product should expect. We can see temperature, humidity, and other factors change as it is shipped back and forth so you can see how your packaging plans stack up, and make adjustments before a full product launch.

Hydrolyzation

Corrosion

Let IMPAK Corporation test your pouches!

Getting a sense of what environments your product will find itself in during shipping can be complicated. Especially when the moisture senstivity is high or even not known, finding the right balance of sorbents can be a time-consuming process. Leveraging our decades of experience we came up with a simple but effective test we now open to our clients. Using a custom suite of testing equipment we can send your product packaged as intended to ship cross-country with sensors recording the environment as it travels. This can act as an informal test to see how the product fares after shipping in terms of moisture damage, as well as provide a baseline expectation of the relative humidity you will be dealing with. From there we can offer suggestions on what kind of barrier film and/or sorbent system you will need to reach your target RH levels as compared to the real-world data. For anyone who looks at the cost of running this test, this can be a cost-saving measure in the long term for anyone whose project might be ruined by excess moisture levels. Compared to tests offered by many professional labs that charge starting around $1500, the IMPAK testing service offers an important element of testing at a much more approachable level.