The History of Stand Up Pouches

In the middle of the 20th century, “flexible packaging” would have been understood to mean bags made from paper or cloth, materials that don’t do a very good job of protecting their contents from oxygen and moisture. For that, people used rigid packaging such as bottles and cans, and many still do today. The advent of Mylar® in the mid-1950s changed the packaging landscape dramatically due to the material having high barrier properties while being much more lightweight and flexible than cans and bottles. The first simple Mylar® bags, however, with their flat, 3-side seal design, did not make an attractive showing on store display shelves.

It wasn’t long before retailers realized that Mylar® could be used to make pouches that resembled brown paper bags, with gussets, or folded pieces of material, on the sides. This allowed a flat pouch to expand to fit much more product, and even do a better job of staying upright on a shelf. A slow revolution in packaging was underway; Mylar® was prized for its ability to provide a barrier to air and moisture comparable to cans and bottles while being lighter and taking up less space. In 1960, an Italian company called Goglio introduced the one-way degassing valve, which paved the way for coffee to be packaged in Mylar® in spite of the off-gassing of CO2 that happens after coffee beans are roasted. Thus the side-gusset bag eventually became the preferred method of packaging coffee in the latter half of the 1900s.

Then, in 1963, Louis Doyen of the French machinery company Thimonnier invented the DoyPack, which is more commonly known today as a stand up pouch. He added a U-shaped gusset to the bottom of an otherwise flat pouch, giving it a base on which it could stand upright when filled. The Doyen style of stand pouch was followed by other styles, including K-seal and Plow Bottom pouches. Although the Doypack was patented in 1968, it would not take off as an alternative to traditional rigid packaging options until the 1980s.

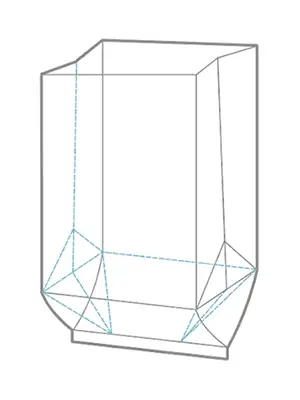

Further innovation of the stand up pouch (or SUP) involved changing the oval-shaped base of the Doyen original for a rectangular base. Due to the nature of foil laminate materials, this necessitated a conversion process that used two webs (film rolls) instead of one, essentially sealing five panels together with eight seals. The resulting block bottom bag (also called square bottom, box bottom, flat bottom, three side gusset, and eight side seal) provides more usable interior volume, more printable surface space, and, arguably, a more appealing look. But it is also a much more costly pouch to produce.

In the 1970s, in response to demand for better flexible packaging for liquids, manufacturers began sealing reclosable rigid plastic spouts into the tops of stand up bags. The first of these new spout pouches were used to package baby food, and though it took time for them to be adopted in other markets, stand up bags with spouts have become a popular choice for many beverages, sauces, semi-liquid foods, beauty products, cleaning products, and for chemicals and powders across a variety of industries.

Types of Stand Up Pouch

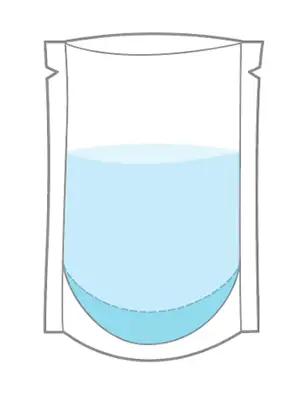

Doyen Pouch

The most common style of stand up pouch is the Doyen pouch (also know as DoyPack or round bottom pouch). It has a U-shaped gusset on the bottom that gives it a rounded base when filled. The pouch "stands" on the base's bottom seals. This style of pouch, often used for food packaging, is recommended for contents weighing less than one pound (0.45 kg), as its ability to stand upright is compromised with greater weight.

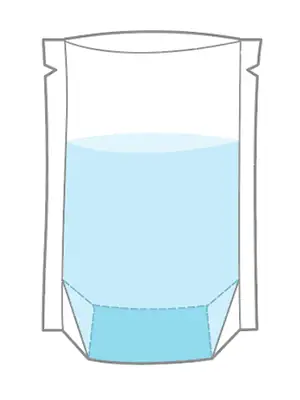

K-Seal Pouch

Rather than having curved seals on the bottom gusset, K-seal or K-style pouches feature angled seals akin to a letter K on its side. Again, the pouch stands up on the seals at its base, which here has a more square shape when filled. The K-seal design makes this pouch more sturdy than the DoyPack, so it is suited for contents in the range of 1-5 pounds (0.45 kg – 2.25 kg). This is often the style of seal on larger stand up bags for liquids.

Plow Bottom Pouch

The most robust of the stand up pouch styles is the plow (plough) bottom, also called a corner bottom or folded bottom pouch. Here, although the sides are sealed, the bottom is not, so unlike the Doyen or K-seal pouches, there is no base made of seals - the product within rests flush at the bottom of the pouch. These pouches are suited for contents weighing over 5 pounds (2.25 kg), such as large bags of flour or salt.

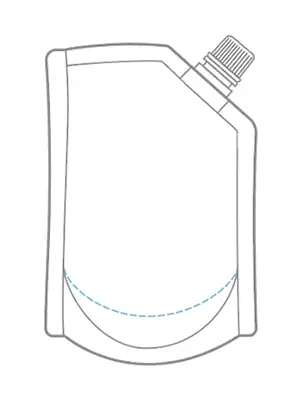

Stand Up Spout Pouch

Spouted pouches represent one of the more recent innovations in stand up pouch design. Technically, many types of pouch can be fitted with a spout, tap, nozzle, or other kind of rigid, reclosable dispenser. But because these fitments are frequently used in liquid packaging applications, stand up pouches are the preferred bag type for the sake of preventing liquid contents from spilling out when the spout is uncapped.

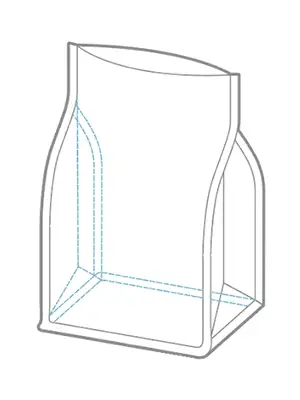

Block Bottom Pouch

Arguably the most high-end style of standing pouch, the block bottom pouch makes a striking presence on a display shelf. It is known by many names, including square bottom, flat bottom, and box bottom; at IMPAK, because of our technical focus, we refer to these as eight side seal pouches. This kind of pouch can be made with different materials on its side panels, and some customers prefer a clear window on at least one side to show off the pouch's contents.

Side Gusset Bag

Although a side gusset pouch is not really considered a stand up pouch, it has a place here as a progenitor to its more refined descendants. For decades, this style has been known as a coffee bag because of its popularity for packaging ground or whole bean coffee. These pouches are notoriously difficult to seal with heat, however, and thus are not recommended when a high barrier is needed.