3D Printer Filament Storage

The past decade has seen an explosion in the viability of 3d printing as more and more people are discovering the flexibility and power of being able to make whatever they need from scratch. From FDM to resin, Industrial applications to home use, additive manufacturing has become an everyday part of many people's lives. Many of those same people tend to discover very quickly the storage and maintenance of filaments can make a huge difference between a library of materials and an unusable waste of money. Exposed Polymers will degrade over time due to Hydrolysis which takes the water molecules in the air and breaks the chemical bond - leading to less rigid or delaminating layered prints. 3D printers commonly use plastic filaments like PLA, PETG, and ABS to (layer by layer) extrude the material into the desired shape. A long thin cable of material wrapped around a spool is fed in, and melted to a working temperature for printing. As strong as some of these Polymers can be, conditions like high humidity can deteriorate a stock of filament - especially while it is stored long term on its roll.

FDM

The most common type of 3D printer is a Fused Deposition Modeling (FDM) printer. It uses spools of thermoplastic filament to melt and build 3d objects layer by layer. The nozzle head and printer bed are all coordinated in their X, Y and Z axis to ensure consistent results across prints. This process of Fused Filament Fabrication (FFF) makes it a cost effective and simple way of prototyping/manufacturing at all levels of investment. This is also the method that has scaled dramatically - becoming refined into industrial applications, while being simplified and shrunk enough to become a device for your home.

Resin

A newer technology that uses mirrors and highly accurate beams of UV light [see stereolithography (SLA) or masked stereolithography (MSLA)] to build highly detailed objects layer by layer from a liquid polymer vat. Bottles of liquid resin should generally be kept in original UV blocking bottles, away from light and temperature variations.

Blue indicating silica and 45% RH is a good indicator it's time to swap out or recharge the desiccant

The Tools: Removing Moiststure from A Sealed Environment

Depending on the material, a good target Relative Humidity (RH) level to try to maintain to avoid saturated filament is around 30%. Some more performant materials will require RH levels closer to 10% to for both storage and production. No matter how low the target level is, there are two main methods of removing moisture from a sealed storage environment:

Dehumidifiers

These relatively compact machines will draw the moisture out of the surrounding air. For those who already own one, this is a good way to get RH levels consistent. While they can't generally get the RH level down to single digits, it can work in small spaces for materials that can be kept at 30% - 50% RH. The downside to this solution is it requires a plug to run the machine, and has a large enough footprint that it is difficult to position in the storage unless built around. Unless you are going custom built, most standard storage solutions are not made to accommodate this style of atmospheric control.

Desiccants

While you might be used to seeing these moisture removing pouches in medical or electronic devices, they can be one of the most efficient and cost-effective ways of removing moisture from a space. For exotic polymer filaments that need RH down in the single digits, a high sorbent pouch made with something like Molecular Sieve is going to aggressively remove moisture from the surrounding area. These packets can also be small enough that they can be tossed into almost any container you are using for the filaments without needing to worry about space. The main downside to desiccants is they can saturate over long periods of time to become less effective until replaced or reactivated. By drying saturated packets for long periods to evaporate the moisture, the same desiccants can be used multiple times.

TIP: Use indicating desiccants (or use a Humidity Indicator), and resuable containers (or DriBoxes), and recharge / reuse your desiccant materials by evaporating saturated beads in a low power oven/dehydrator.

Measuring Relative Humidity

In either case, there should be something that will indicate if the RH level of the storage unit starts to rise. For most basic storage a Humidity Indicating Card is a simple way to know the filament environment has not exceeded the target RH. For more accurate needs, an electrnoic RH reader can be included in the container/vacuum seal bag - but requires battery management.

Tips For Filament Storage and Moisture Mitigation

Polymers exposed to the bare environment will degrade over time due to Hydrolysis which takes water molecules in the air and breaks their chemical bond - leading to less rigid or delaminating layered prints. While not as dramatic in materials like PLA, others like PETG or ABS will become unworkable if left out too long. Each filament and manufacturer will have different recommendations, but there are some basic levels that are safe for most printer setups.

Left print made using saturated filament

- Use air-tight container to store spools

Many enthusiasts or first time printers make a filament shelving system to display their "collection". Unless you are controlling the environemnt for the entire room, this will lead to issues with filaments.The key to keeping filaments dry is making sure they are in a controlled environment. This can mean a sealed bin, or a high barrier plastic bag like the one the spool came sealed in - anything sealed and small enough so you are not fighting against the natural Relative Humidity every time. It varies across materials but you need to avoid RH levels greater than 30%, but closer to 10% is ideal. While some PLAs can keep working closer to 50%, ABS or ASA need a consistently dry environment. - Inspect Spools

When unloading and loading filaments, take a moment to check for any abnormalities in the material. Unwound or loose spools can ruin prints. While it might make sense to keep brand new spools sealed in the plastic bag they were shipped in until use, there is a chance the filament or the bag has humidity sitting inside already. For both new and stored filaments, if you see the vacuum sealed bag is looking a little loose, there could be a puncture that has negated the point of that air tight barrier. The most surefire way to make sure the materials are in good condition if there is any doubt, is to remove it from the stock packaging and allow it to dehumidify using your own S.O.P.

- Maintain Low Humidity Environment

Hitting a target RH of 10% can sometimes be difficult. In addition to the airtight container or vacuum bag, it is important to use desiccants in the sealed environments to provide a consistent storage space. For most use cases a packet or container of indicating silica gel will work great. For more sensitive materials we recommend using molecular sieve to more aggressively lower the RH in the container. Add a Hygrometer and/or a Humidity Indicating Card to give you an idea of how the seal is holding. While an HIC is pretty simple in how it displays levels by color changing ink, it also requires no batteries once in place.

Desiccant Options

You are probably already used to seeing mosture fighting packets in medical or electronic devices. They can be one of the most cost effective ways to maintain the humidity of a space. These are the key to maintaining regular atmosphere for printing materials - and are a must for those who need a large amount of filament storage or have a high volume production line. Some things to consider when looking at desiccants:- Packets - Come in descrete sized individual pouches (or as a strip) designed to control specific amounts of empty space.

- Bulk - Comes as loose beads to refill a Dri-box, or line a container. The most cost effective way to keep your filaments dry.

- Silica Types - Most people looking for filament storage will use the indicating variety so you don't have to wait to see raising RH levels to know they need to be replaced.

- Molecular Sieve - A vry aggressive desiccant. Ideal for materials that require that consistent 10% humidity level, or to dry out a saturated roll.

TIP: If you want to deal with fewer airtight containers, you can invest in a Dehumidifier to control the RH of the storage room itself. This can be as simple as plugging in a machine, but to get good results you will need to be in a smaller enclosed space. This can work well for some basic PLA print farms, getting the overall RH down toward the 10% range is very difficult using a machine like this.

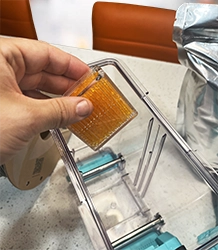

- Active Drying Environment

When all else fails you can also invest in a more active drying solution. There are 1-4 roll drying boxes available, and some can even feed out to the printer. They are designed to draw the moisture out of any saturated films like a gentle oven - and keep the humidity out. They can take a lot of the problems with humidity out, but do require a little forthought to what filament you will need a day or two in advance. You can also use stronger moisture absorbers in a sealed environemnt to achieve similar resuilts. Molecuilar Sieve has been seen as an effective method of drawing moisture out of a saturated environment.