Why is Molecular Sieve the Best Desiccant?

DESICCANT KNOWLEDGE HUB

Molecular sieves are synthetic porous crystalline aluminosilicates which have been engineered to have a very strong affinity for specific sizes of molecules. The definitive feature of the molecular sieve structure, as compared to other desiccant media, is the uniformity of the pore size openings. There is no pore size distribution with molecular sieves; the pore size on the molecular sieve particles can be controlled as part of the manufacturing process. The most commonly used pore size is 4 angstroms (4A) although 3 angstroms (3A), 5 angstroms (5A) and 10 angstroms (13X) are available. This distinctive feature allows for the selection of a molecular sieve product which can adsorb water vapor yet exclude most other molecules, such as volatile organic compounds (VOCs), which may or may not be present in the package.

Molecular sieve is the best desiccant based on technical performance characteristics. Its ability to adsorb moisture, in this case water vapor, is so pronounced that it can remove trapped H20 molecules from a fully saturated silica gel bead, which in turn changes the silica gel back to its original cobalt blue color.

Watch molecular sieve extract moisture contained in other products!

The selective adsorption characteristics of molecular sieves can be useful when it is necessary to dry a package or environment without removing other desirable compounds within the system. Molecular sieve can trap water vapor to temperatures well past 225°C in some cases, and due to its high affinity for water vapor, molecular sieve is able to bring the relative humidity (RH) in environments down to as low as 1% RH.

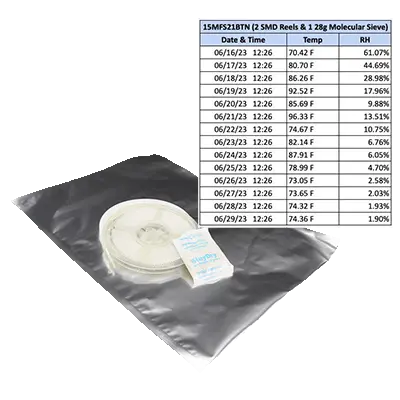

Case Study 1:

We ran a "real world" test with a molecular sieve packet using our 15MFS21BTN MylarFoil bags. We sealed 2 SMD reels inside, a 28g Molecular Sieve desiccant packet, and measuring equipment, then shipped these back and forth across the country, taking measurements of the temperature and relative humidity on each day of the journey. The desiccants quickly removed the moisture inside - from a high of 61% down to less than half the relative humidity after 2 days. This test illustrates the importance of keeping in mind the transportation conditions of packages and how that can factor into the preservation tools used. While a high temperature spike saw a small rise in RH level, the molecular sieve packet kept the levels manageable, and continued to work for the remaining time in transit. Unlike silica gel, there were no problems having the moisture escaping (desorbing) back into the package during those temperature spikes.

Case Study 2:

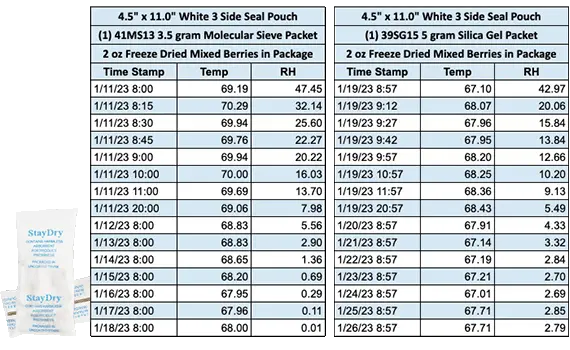

Exploring ways to further ensure lyophilized products like freeze dried berries stay dehydrated, we looked at the differences between silica and 13X molecular sieve pakcets. The results in the chart show the clear difference in how much relative humidity molecular sieve packets can absorb relative to the silica.

What makes molecular sieve the best desiccant:

- Highest adsorption capacity at low relative humidity.

- Ability to extract moisture contained in other products.

- Will not desorb moisture into the package when temperatures rise (unlike silica gel).

Purchase 41MS13 molecular sieve packets below. Available 5,000 per case or 100 packets per pouch:

5g Silica packet vs 3.5g 13X molecular sieve packet in relative humidity comparisons - molecular sieve pouches can reduce the in-pouch relative humidity far below what you can achieve with just silica

As any seasoned packaging engineer dealing with moisture-sensitive products will tell you, the most critical question to ask is...

"What RH do you NOT want your product to see?"

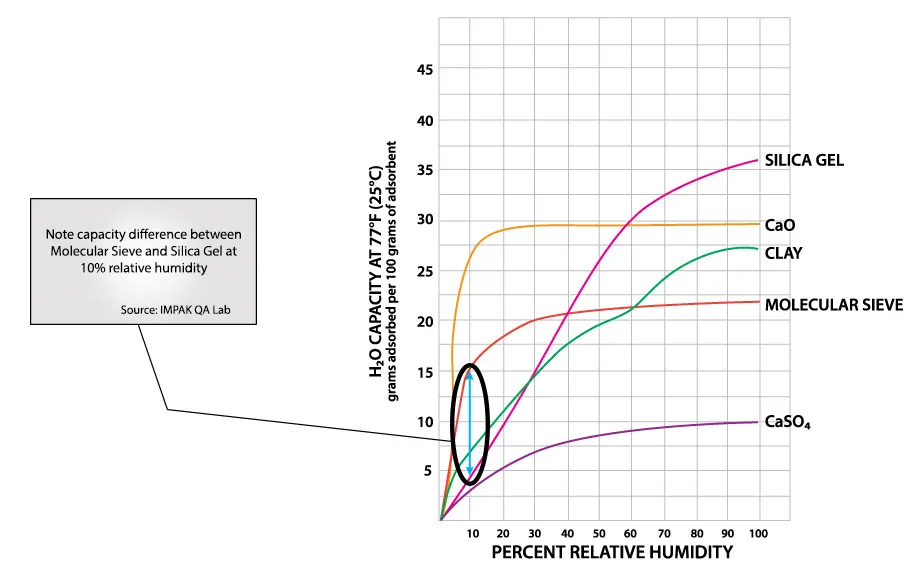

The answer to the question, "What relative humidity do you not want your product to see?" is, in the case shown below, 10 percent:

Example: You’re in product development creating a medical instrument or diagnostic test. You’ve decided that you need to maintain the humidity in the package at 10 percent or less. Thus, to answer that Packaging Engineering question, “What relative humidity do you NOT want your package to see?” The answer, in this case, is 10 percent relative humidity (see the graph above and note circle around 10 percent relative humidity.) In that environment, the capacity for silica gel is 4.6 percent and the capacity for molecular sieve is 15.2 percent (data obtained from IMPAK QA Lab). In other words, a 3.5-gram packet of molecular sieve working in a 10 percent environment has more than three times the capacity of silica gel. This is the most important concept to understand in all of adsorbent technology.*

10 percent is often a target relative humidity to maintain long shelf life in lateral flow diagnostic devices. Five percent is the target relative humidity in the bake-out procedure for some semiconductor and microprocessor devices.

One of the more well-known specifications that uses two particular relative humidity environments is military packaging. MIL D3464 Revision E is based on a specific set of results and references two particular humidity-based environments: 20 percent RH, relatively low, and 40 percent RH, relatively higher but still low enough to prevent corrosion. The military specification calls out that the sorbent utilized to produce a military-grade desiccant package must be able to adsorb three grams at 20 percent relative humidity and six grams in a 40 percent relative humidity environment. What does this mean? As the Technical Director of our company in the 1990’s once said, “If for some reason the dirt in your backyard was so prone to accept moisture that 10 grams of it would pick up three grams in a 20 percent environmental chamber and also pick up 6 grams in a 40 percent environmental chamber, you could enter the field of military-grade desiccant packaging immediately.” Why is this? To meet that specific characteristic that is the prime directive of the MIL D3464 desiccant package it must be able to pick up 3 grams at a 20 percent environment and 6 grams in a 40 percent environment. Most sorbents, i.e. silica gel and clay, tend to need 30 to 33 grams to meet that requirement. Molecular Sieve needs less - almost 20 percent less. Unfortunately, Molecular Sieve is significantly more expensive than silica gel or clay, or despite the reduction in total packaging cost it needs as a product, it would be the dominant sorbent used in military applications. If this all makes sense to you on one read, you should obtain an honorary Packaging Engineering degree in the area of sorbent technologies.

*Note: Calcium oxide has an extremely high capacity despite its very slow adsorption rate. The use of Calcium Oxide is almost exclusively found in the United States in military applications due to its flammability in wet environments. It is also commonly seen worldwide in Japanese dried seaweed products where it is often referred to as slaked lime. We reference this only to demonstrate the global sorbent knowledge that is part of IMPAK Corporation’s skillset.

For more information on desiccants and humidity indicators click the links below: