Advancing Vacuum Sealing Technology to ship seafood UNFROZEN

Ship Seafood via sea freight UNFROZEN while maintaining Freshness, Quality and Extending Shelf Life.

BLUE  OCEAN PROJECT

OCEAN PROJECT

100 inch (2540 mm) Custom Vacuum, Gas Flush Heat Sealer

In 2017 IMPAK was contacted by a firm with a challenge; to devise a system to transport fresh fish and other proteins virtually anywhere in the world without the need for being frozen. Their concept required a large, 100-inch seal length, heat sealer with vacuum AND gas flush to suspend time and force out destructive gases. Not only does this save on expensive airfreight, it also eliminates environmentally harmful Expanded Polystyrene (EPS) packaging.

The customer has a heat sealing machine that was produced by Aline Corporation (www.alinesys.com). Although Aline went bankrupt in 2012, IMPAK Corporation’s Machinery Group is committed to supporting and manufacturing all of the sealing units that were previously produced by Aline. Our client is requesting several additional sealers to facilitate their expansion in Scandinavia and South America.

Currently, IMPAK’s Machinery Group Engineering staff takes on 1 to 2 large scale custom machine projects annually. The key criteria are that they have to be either vacuum or temperature control related sealing equipment. We will refer to this project as Blue Ocean (in order to keep the primary customers name confidential.) This entire project came down to three critical elements:

- ULTRA LARGE SCALE MULTIPLE GAS MIXING AND FLUSHING

- VERY LARGE SEAL AND VACUUM TECHNOLOGY (100 IN/2540 MM)

- ENGINEERED, RUGGED MEZZANINE FRAME FOR SEALING X KGS AT A 4 METER WORK HEIGHT

The Scope of Work (SOW) required that the sealer accomplish the following:

- Intelligent gas/vac/sealing System Features and Specifications**:

- 400 Volt input power

- Lead time 13-15 weeks

- Fast cycle times – Target 8 to 10 minutes for complete vacuum / gas flushing / heat seal

- 100% seal and monitoring system to ensure integrity of seal

- Vacuum or pressure decay time test on first cycle

- Multiple cycles (Adjustable)

- Pressure not to exceed 1” WC (Water Column) - Adjustable

- Vacuum not to exceed -1” WC (Water Column) – Adjustable

- Automated mixing system for 2 gases – N2 and CO2

- 1st Vacuum and back flush process with pure N2 ~ 3 Cycles – Adjustable

- 2nd Vacuum and back flush process with blended CO2 and N2 (example 75/25 – 70/30) 3 Cycles - Adjustable

- Final “fill” is precise volume of blended gas to weight of product – Adjustable

- Mezzanine to be included

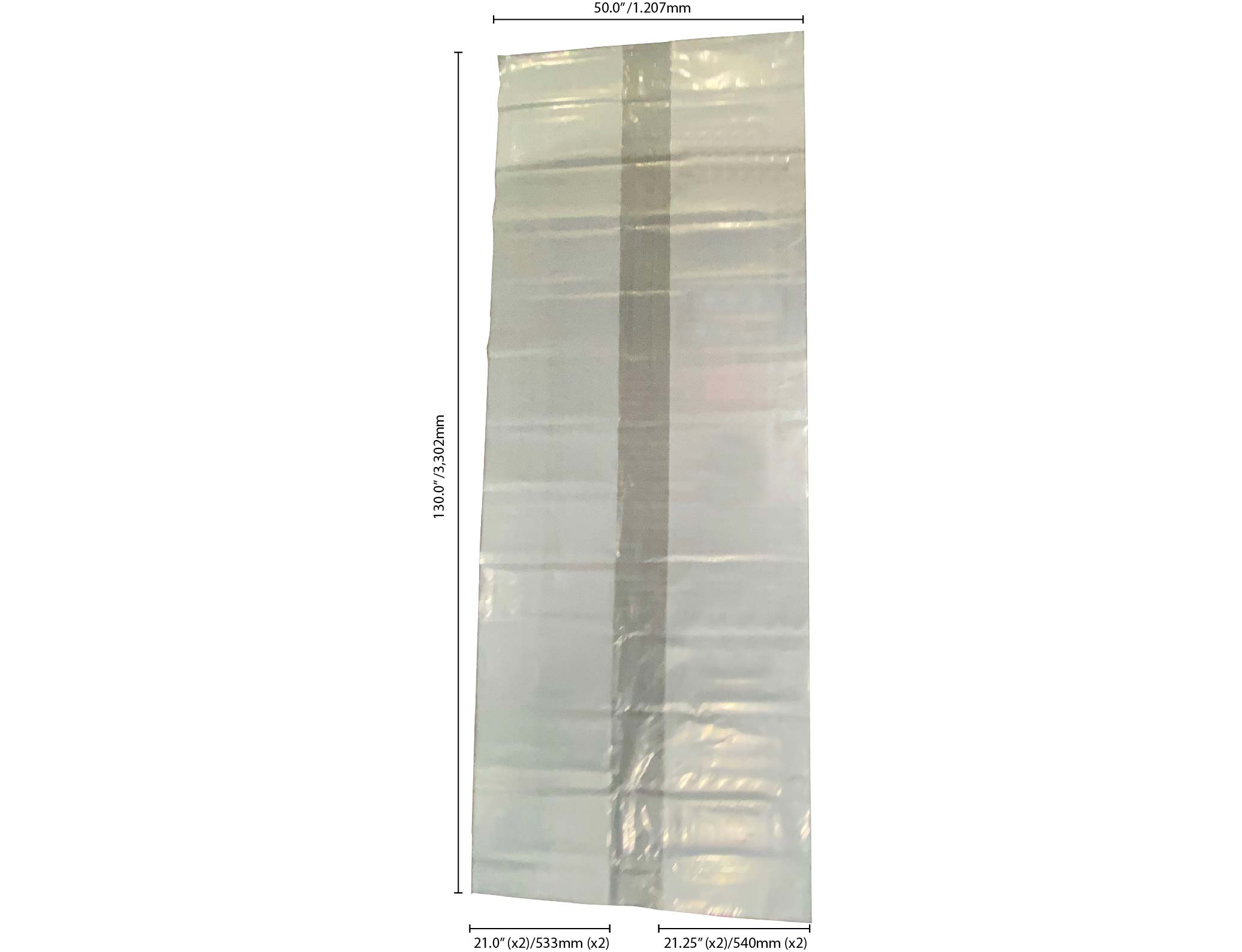

- Able to seal High Strength Nylon Coextruded gusseted bag with dimensions 130” X 50.” (Palletized Product envelope: 48 X 40 X 60-inch.)

The customer requirements for the sealer:

Heavy Duty 100” Vertical Gas Flush/Vacuum/Heat Sealing Unit with the Following Features:

- 0.375” dual heating elements

- Temperature controlled heating elements

- 100” max seal length

- Powder coated steel frame

- Intelligent gas/vac/sealing System

- Pneumatically actuated seal bars

- Semi-automatic bag spreader and holder

- Master On/Off switch

- Low pressure safety descent

- Foot pedal operated

- Emergency stop button

- Open back for material feed through

- 220-240V/50Hz/55 Amp

- Made in the USA

Our engineering staff was confronted with many challenges while designing and building this sealer. Below is a list of new processes and systems that were developed and incorporated just to meet the project requirements.

- A customized nozzle to support air flow rates up to 3,000 liters per minute was designed.

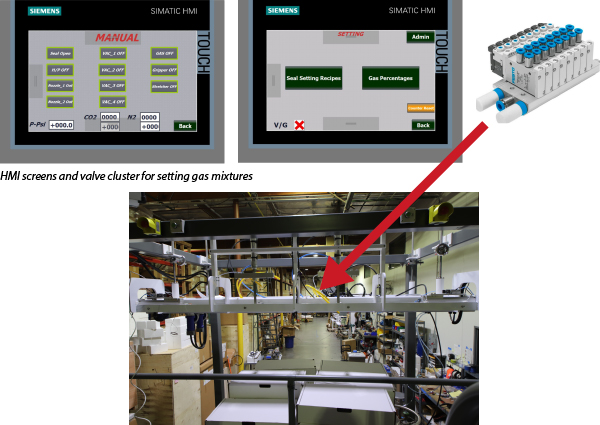

- The largest challenge faced by our design team was the development of the precice, automated, electronic gas mixing system that flushes and purges six specific mixtures of N2 and O2. Final fill volume is based on gross weight of palletized product.

- Incorporate electronic sensor capable of providing an instant status report of pressure in the bag.

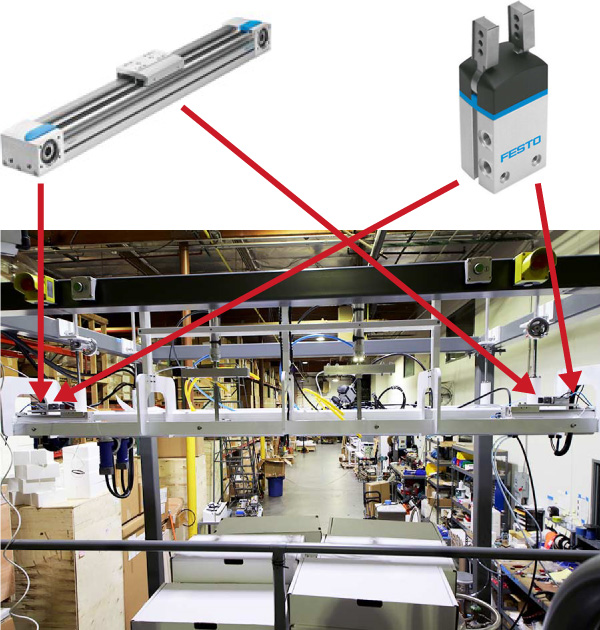

Red arrow indicates sensor nozzle - Develop bag holder / stretcher with servo operated grippers to facilitate one-person operation.

- Ergonomic, customized, working platform for one-person operation and conveyor flow through of palletized product.

- Temperature sensor on N2 input flow to ensure continuous gas flow. (Avoid need for radiator.) Photo shows monitor of actual readings.

- Integrated Remote Communication Platform (RCP) so that IMPAK can access the sealer remotely.

- Designed and built for a 111” (2.8 m) height with 12” (300 mm) maximum adjustment.

- For reference below is a photo of their existing Aline heat sealer.

Blue Ocean Project Time-lapse

Watch time-lapse video of IMPAK Corporation construction of a 100" (2,540mm) wide vacuum sealer for fresh - not frozen salmon production in Norway.

If you are interested in learning more about this sealer or IMPAK’s custom machine capabilities, please contact us at flprocessing@impakcorporation.com