Chamber Sealer and Flexible Packaging Solutions

Gramatech Chamber Sealer and Flexible Packaging Solutions Help Chubby Snacks Achieve Success at Every Stage of Explosive Growth!

Flexible Packaging Solutions for Every Stage:

Chubby Snacks had been using stock pouches that had to be cut down and labelled by hand. We helped them progress to using rotogravure preprinted pouches. (See stages below.)

The original unprinted, unlabeled pouch is available for purchase:

https://www.impakcorporation.com/flexible_packaging/BNK03Z

IMPAK designed and produced the second generation, custom printed pouch for Chubby which is now available for purchase here (unprinted):

https://www.impakcorporation.com/flexible_packaging/ANK025TNRC

Challenge: Keep the packaging process simple and provide a pathway to increased throughput as sales exploded.

IMPAK helped Chubby Snacks bring an innovative, organic twist to the peanut-butter-and-jelly-sandwich through explosive growth stages and rapidly increasing throughput requirements. Their creative and simple approach to ingredients, selection, and product development was used to help IMPAK develop the right packaging process and flexible pouch. Their products have no preservatives or stabilizers and are quite soft, so selection of the right pouch material and sealer were important. A chamber sealer with gas flushing capabilities provided the preservation level and delicacy required by Chubby Snacks.

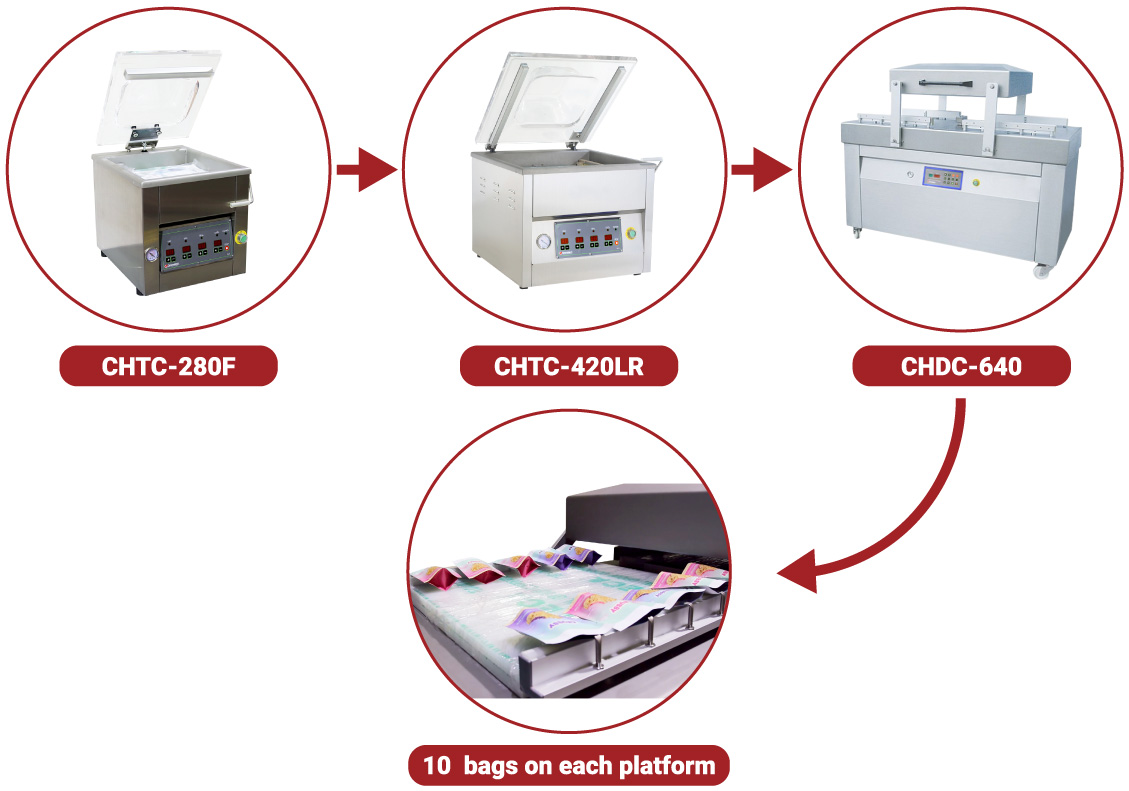

Chamber Sealer Solutions for Every Stage:

First, a Gramatech entry level, table top chamber sealer with gas flush option was used for experimentation and startup volumes. Next, a larger chamber sealer was needed to meet accelerating demand for their products. Last, a double chamber sealer was chosen to meet the demands of a full production schedule.

1. Stage 1: Gramatech Tabletop CHTC-280F Chamber Sealer (April-2020)

- With optional gas flush, Chubby Snacks was able to launch their product and immediately achieve increased shelf life.

2. Stage 2: Gramatech CHTC-420LR: Stainless-Steel Chamber Vacuum Sealer (Nov-2020)

- Larger chamber size and longer seal bars increased throughput from 2 pouches per cycle to 8 pouches per cycle.

3. Stage 3: Gramatech CHDC-640: Double Chamber Vacuum Sealer (March-2021)

- Much larger dual chambers and longer seal bars increased throughput from 8 pouches per cycle to 20 pouches per cycle.