Why Should I Get a Dual Heat Sealer?

"It's the MOST recommended upgrade for our sealing machines."

EVS-800 Dual Heat All-Electric Vacuum Sealer

Double impulse, dual element, top & bottom heat, bi-active seal - this option, by any of these names, is hard to beat. Why do IMPAK's heat sealing experts so strongly recommend it?

Entry-level heat and vacuum sealers generally feature a single heating element to create seals. This element applies heat to one side of a pouch, while the bar or surface on the other side produces no heat, but is usually covered in PTFE (Teflon). This type of sealer is widely used for sealing light duty poly bags.

For many applications, however, a single heat bar is insufficient. In fact, many customers have approached us because their single element sealers have not been up to the task, causing increased wear and tear, frequent parts replacements, and even repairs for damaged machines.

Reasons to invest in a sealer with top and bottom heating elements:

- Heavy Duty Materials - Pouches made from thick, high-barrier materials, including those with a foil layer, often require bi-active sealing for reliable results.

- Side Gusset Bags - Gusseted bags, wherein the material is “folded in” on the sides, effectively have four rather than two layers of material to seal through.

- Faster Throughput - With two heating elements, quality seals are achieved with shorter seal times, especially for thicker materials.

Here's what customers that opted for double element sealers have said:

“It’s faster, it’s a better seal - why would I get anything else?”

- Michael B, Chicago Nut Roaster“Our [product] bags are really thick, really high barrier. The double element sealer is the only one that does the trick.”

- Jorge A, San Diego Pharma Supplier“We always had trouble getting a good seal on our classic coffee bags. Since we switched to a dual heat sealer, no problems.”

- Samantha T, Seattle Coffee Roaster“Definitely speeds up bag sealing. Thanks for the recommendation!”

- Nazeem M, Dallas Food ProducerDoes your current sealer have one or two heating elements?

Single element sealer

Dual element sealer

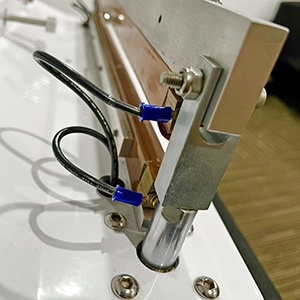

If you look closely at the seal bars on the heat sealer(s) your company uses, you should be able to quickly determine whether you're looking at a single or dual element configuration. (For safety, be sure to turn off and even unplug the unit before close inspection.) Some of the things to look for include:

- Visible wires connected to both the top and the bottom seal bars

- If no wires are visible, seal bars that appear similarly built, often with caps on the ends

- On some single heat machines, only the side with the element is covered with Teflon

If you have had issues with producing a reliable seal on your bags, you may want too consider upgrading to a double element sealer. Contact IMPAK to ask one of our sealer experts about whether a dual heat sealer will benefit you.

IMPAK Sealers with Dual Elements

Dual Element Standard

Sealers manufactured by IMPAK that come with dual heating elements standard, or with a choice between single and dual elements:

Dual Element Option

Sealers that are built with a sinngle heating element standard, but can be modified at customer request to use two elements:

Dual Element Unavailable

Some kinds of sealers, due to their design, simply cannot be modified to have two sealing elements working in tandem. This includes RapidSealer™ Band Sealers and Chamber Vacuum Sealers, as well as others.

If you require a double impulse sealer and the units available here don't fit your needs, IMPAK's technicians will be eager to discuss how to build a machine that suits your application.