EV Battery Technology

The growing demand for electric vehicles has spurred a great deal of innovation geared toward improving EV batteries. Manufacturers are racing to develop batteries that have more energy capacity, faster charging capability, better power delivery, lower materials and production costs, and as close to zero volatility as possible. Much of today's research involves finding a superior chemical composition for battery cells; promising alternatives to NMCA and LFP lithium-ion technologies include lithium-sulfur, sodium-ion, and oxygen-ion cells as well as improved solid state batteries. At the same time, there is robust debate over the best format and materials for EV battery cells between cylindrical, prismatic, and pouch cell models, with a growing number of technology developers favoring pouch cells as the format that will safely and efficiently scale to meet the needs of a clean energy future.

Thermal Management

One of the most significant challenges currently being addressed in the realm of battery technology is thermal management. Electric vehicle battery operation generates an enormous amount of heat, so much so that cooling systems can become overtaxed, often resulting in a thermal runaway scenario and catastrophic system failure. On top of that, tremendous heat is generated when charging an EV battery. Manufacturers are working to improve performance and reduce charging time by increasing charging speed, making the challenge of reducing heat stress on EV batteries even more critical.

EV battery cooling has undergone many technical evolutions in recent years. Passive (air) cooling is no longer sufficient for today's batteries. The primary alternative has been relatively dense, bulky battery coolant panels made of materials such as extruded aluminum through which liquid cooling agents are passed, but these parts add a significant amount of weight to an already heavy battery system. They are also burdensome to manufacture, involving massive material and energy costs.

Laminate Materials Present a Way Forward

Some of the latest innovations in the race to efficiently cool electric batteries and prevent thermal runaway propagation involve the use of lightweight, high temperature grade structures to create laminate-type heat radiators, also known as laminate film coolers, that maximize cooling efficiency. Laminate film coolers (or "lamicoolers") made from films such as SPALF that have an ultra-thin aluminum foil component have the advantage of being easily thermoformed and having high thermal conductivity and corrosion resistance. This makes this type of laminate film an ideal structure for a simple and effective coolant panel for EV batteries.

IMPAK supplies a well-known EV manufaturer with a product made from an extremely heat-resistant laminate which has a sealant-layer temperature contact capability that makes it ideal for high heat applications. Given the exacting technical requirements involved in the creation and implementation of these battery systems, IMPAK understands that, as a supplier, we are responsible for delivering a product that meets or exceeds the customer's specifications. Our materials team rigorously tests each product to know its capabilities and limitaions, and works with clients to find both materials and techniques that suit even the most demanding applications.

Pouch Cells

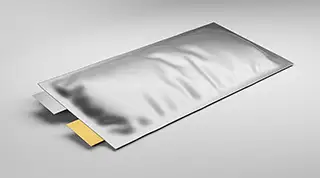

Example of an EV battery pouch cell

Pouch cells are flat, pouch-shaped battery cells made from flexible laminate materials that incorporate a cathode, an anode, and a separator. They are used with a variety of battery chemistries, with liquid, gel, or solid state electrolytes, and are emerging as the most promising format for battery cells. Pouch cells are used in consumer electronics, electric vehicles, and other power storage systems because they offer an alternative to rigid battery cells. They are more lightweight, more space-efficient, capable of higher energy density, better at thermal management, and less expensive to manufature than cylindrical or prismatic cells.

IMPAK Corporation has a long history producing robust flexible film structures for demanding industrial applications, including the storage and transport of volatile chemicals and packaging for extreme temperatures. We are experts in creating laminate structures with capabilities beyond what is commercially available. If you're in need of a heat resistant flexible film and you are concerned about the propensity of the sealant layer to hold moisture, even at low levels, consider using our PAKSAFE320 material, which has a hydrophobic sealant layer that has much less of an affinity for moisture than most laminate structures. IMPAK Corporation is highly experienced in engineering flexible film structures to exacting customer specifications, notably in the EV battery space.

Industry researchers are finding that the benefits of laminate film materials include:

- lower materials cost

- source reduction

- ease of manufacture

- corrosion resistance

- component weight and space savings

Contact us today and take advantage of IMPAK's decades of materials expertise to find solutions to your challenges.