Healthcare Technology

IMPAK Corporation supports innovators in the biotech, pharmaceuticals, diagnostics, and life sciences community like no other company. We are the partner of choice for scores of companies in need of a complete solution that utilizes flexible barrier packaging, heat and/or vacuum sealers, desiccants, oxygen absorbers, or other specialty sorbents, and we continue to build relationships in this ever-expanding field. One of our core strengths is healthcare product development; we bring decades of knowledge to bear in finding ideal solutions when your packaging needs to be as perfect as the product inside.

Besides being the preferred source for high quality products used in the development and dissemination of next-generation medical technologies, IMPAK has a team that can solve the challenges of protecting sensitive materials with intensive handling requirements. If one of the standard 53 materials on our production floor isn't adequate for your application, we will engineer a custom laminated structure to fit your needs. Or if you are having problems with your supply chain, we have demonstrated numerous times an ability to duplicate products at higher quality levels than previously produced. We also offer an array of services that are of significant value to our healthcare partners, including package testing that yields technical data on RH levels throughout the shipment cycle, and provision of sealing equipment that is clean room ready.

Four examples of how IMPAK supports healthcare product development

In the process of helping these companies with their challenges, IMPAK was able to demonstrate three things:

- We have the patience to work with customers who require copious time in their decision-making process - in one such case, upwards of five months - and then provide the final product with a very fast turnaround.

- We can produce high quality printed pouches even at unusually low order volumes. For each of the customers below, order quantities for each custom pouch were for no more than 1500 units, one of them only 500!

- We can integrate custom printed pouches with high quality sealing equipment and options such as our Production Improvement Platform, which is a productivity game changer.

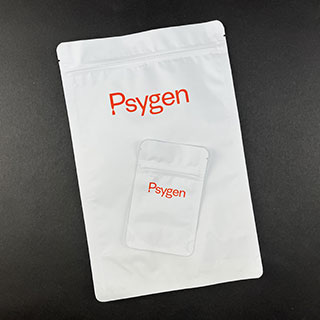

Case Study 1: Small Volume Custom Pouches for Early Stage Pharmaceutical Development

A cutting-edge producer of pharmaceutical compounds was involved in early stage product development. They required sets of drug-contact barrier pouches in multiple sizes at small volumes, with separate opaque custom printed outer packaging to prevent photodegradation (light damage). With our decades of experience in determining the appropriate barrier structures for safe handling of moisture and light-sensitive products, IMPAK determined that, of our 53 materials on the production floor, our transparent PAK48MT2500 structure would provide the specific barrier properties required for the inner pouches and the lightweight feel that the customer desired.

The outer bags, produced from IMPAK's PAKVF4 high moisture barrier foil-based laminate, was converted into five different sizes of tamper-evident ZipSeal™ pouches to this customer's specifications. IMPAK exceeded the customer's expectations with an extremely fast turnaround of only three weeks for all of these pouches. On top of that, we did so with very low order quantities - 500 of each pouch. Because we understand the challenges of early stage pharmaceutical development, we will muster our resources to support the goal of safely bringing new drugs to market. These pouches provided extraordinary protection from moisture, oxygen, and light, all of which were crucial for keeping this customer's product in excellent condition.

Case Study 2: Custom Lamination for Comparison Testing

A medical product innovator asked IMPAK to produce a custom printed pouch for a therapeutic gel, but could not decide between IMPAK's PAKVF4 structure and a custom lamination that was 1 mil (25 microns) thicker than that standard material. They decided to engage IMPAK to produce only 1000 of each pouch, which is only an additional 170K square inches of customer-specified laminated structure.

IMPAK has a lower minimum requirement for custom lamination than virtually any company in the industry; one 48" x 3000' roll is often our minimum requirement. Using laboratory-grade laminators, we produced sufficient raw material to provide this customer with the two different pouches (including the custom-laminated structure) they needed to run a comparative trial for their gel. We recognize that development of new medical products is a fraught process, and we have the patience to help our customers determine the best path forward for success.

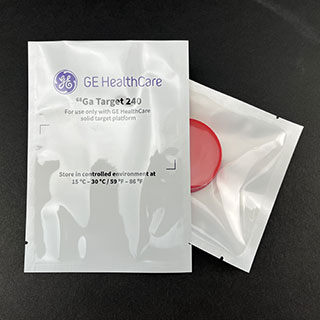

Case Study 3: Integration of Customized Pouches and Sealing Equipment

A major provider of isotope and spectronomy services contacted us to procure safe packaging solutions for handling and distribution of solid targets made of a radioactive isotope. IMPAK produced a high barrier 4.25" x 6" pouch that fit their needs, including having a clear window on one side, tear notches, and custom printing, at an order quantity of only 500 pouches!

Additionally, IMPAK provided them with a chamber vacuum sealer that could give these pouches a secure and virtually air-free seal. We also created a Production Improvement Platform, or PIP, to be used with this sealer. The PIP is a sturdy HDPE plate custom-designed to hold pouches perfectly in line with the sealing element inside a chamber vacuum sealer, making pouch placement easier, reducing production time, and ensuring accurate seals.

The video below demonstrates how the Production Improvement Platform can speed up the process of vacuum sealing your product.

Chamber Vacuum Sealer with Production Improvement Platform

Case Study 4: Helping Get Urgently Needed Medical Product to Market Quickly

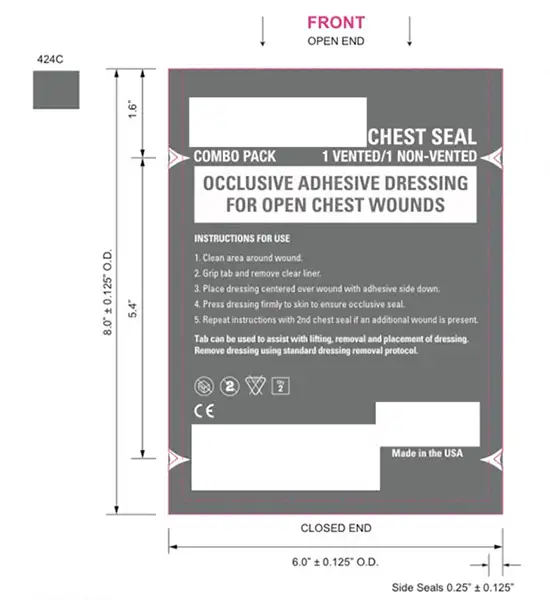

In this case, the bonus fourth in our "trilogy" of examples, a maker of unique occlusive wound dressings for use in combat situations came to IMPAK in need of pouches for their product. This customer’s needs were successfully addressed in a three-step process.

They originally asked for 25K label-ready pouches printed with a flood coat single gray color (Pantone 424C) and with two sets of tear notches. However, due to the sudden urgency of international conflicts, the 3-4 week time frame for these custom pouches would not suffice; they needed pouches in one week.

IMPAK maintains several million three-side seal barrier pouches for a wide range of customers in the biomedical industry. Fortunately, one of these bags fit the needs of this customer, but because the pouch chosen from existing inventory did not have dual tear notches, our production team arranged to add the additional tear notches offline. The first 5000 of these were produced and shipped in 168 hours, and an additional 5K were delivered 168 hours after that. The urgently needed pouches were all delivered in less than one week.

The original order of 25K color label-ready pouches was delivered shortly thereafter, with a 552 hour turnaround time. The customer also asked IMPAK to produce another 25K pouches, fully printed with their artwork. In order to get a better cost, they accepted our standard lead time of 7-8 weeks, and from purchase date to ship date was 1344 hours.

Contact us to take advantage of our experience and expertise to solve your challenges.