Case Study: Custom Lamination

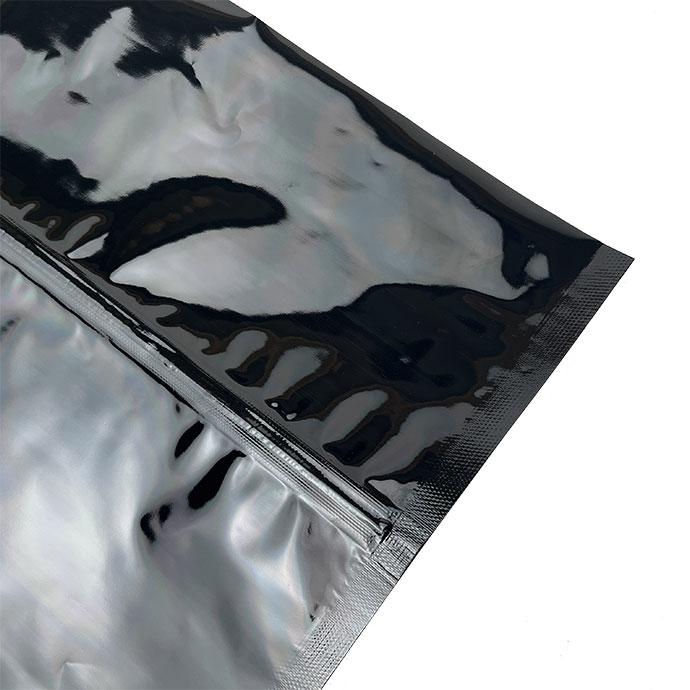

Example of this material

As a U.S.-based producer of technical barrier films, IMPAK primarily works with imperial measurements (e.g., feet, inches, miles, pounds, Fahrenheit degrees). We were approached by a U.S. pharmaceutical company that was procuring their material overseas and had run into significant supply chain issues. Their specification provided to IMPAK was in metric units, which was no issue for our engineers who regularly work with clients around the globe.

The material structure: PET 12µ / AL 6µ / ONY 15µ / CPE 90µ

In addition, the specification contained a very unusual sealant layer - cast polyethylene. The customer called for this material because their application, in-process pharmaceutical development, mandated a film that is non-toxic, odorless, chemically stable, and possessed of high barrier properties. In combination with the aluminum and nylon layers, this material provides a superior barrier to moisture, has a high tensile strength, and has allowed the customer to maintain absolute sterility for their product.

This item has very limited availability as it is produced to strict specifications for a highly hygroscopic pharmaceutical compound; the pouches on hand represent an overrun in excess of the customer order. However, the material can be produced and converted into pouches or tubing of any format. Contact IMPAK to inquire further.

More Abbout Cast Polyethylene (CPE)

CPE is formed when polyethylene polymer is extruded through a die onto a roller in order to render a thin film. Because this casting process takes place at high temperatures, the result is a film with low variance and good elongation propertries that can be produced quickly. When incorporated with structures that provide the desired qualities, it makes an economically prudent choice for a sealant layer. CPE films are particularly popular for food packaging applications, and are desireable in the medical / pharmaceutical field because they are odorless, non-toxic, and well-suited for sterile / anti-microbial applications. Benefits include:

- High tear resistance and tensile strength

- Chemical stability

- Good H2O and O2 barrier properties

- Transparency - excellent for clear structures