Pinholes in Foil Structures

Foil laminated structures are often liable to have tiny, often microscopic holes or perforations called pinholes. These holes can compromise the integrity of the foil's barrier properties, leading to issues like leaks, contamination, and reduced effectiveness in containing or keeping out gases, liquids, or light.

A foil layer will provide a much better water vapor and oxygen barrier compared to films without foil. However, a foil layer less than 1.0 mil thick is rarely perfect. Typically, as the thickness of a foil layer decreases, the more likely it is to have pinholes. Structures with a 1 mil foil layer are guaranteed to have no pinholes when produced.

| Foil Thickness (in) | Typical Pinhole Count/ft2 |

|---|---|

| 0.00025 | 41 |

| 0.00030 | 20 |

| 0.00035 | 12 |

| 0.00050 | 6 |

| 0.00070 | 1 |

| 0.00100 and above | 0 |

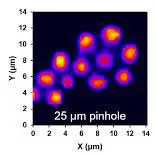

Because pinholes are typically only 10 to 50 microns in diameter, they usually do not have a significant effect on the structure's barrier properties. However, if the pinhole goes through the laminate completely, water vapor, oxygen, and sterile barriers may be lost. Additionally, rough handling, bending, or scraping of the foil can cause mechanical stress and exacerbate pinholes.

Pinholes in foil are particularly concerning when the foil is used for applications that require a high degree of containment, such as packaging perishable foods, pharmaceuticals, and sensitive electronic components. In these cases, the presence of pinholes can compromise the effectiveness of the packaging material and lead to spoilage, contamination, or damage. It is therefore adviseable to use structures with more robust foil layers.

If you are concerned about how pinholes may affect the barrier properties of your laminate structure, please contact one of our technical experts about testing your packaging or choosing a material that will ensure the highest possible barrier.