Custom Laminations

"When you need ONE roll, and no one else wants to do it, IMPAK will make it happen."

- Operations Manager, UK-based diagnostics firm *

* BarrierFlex™ produced in 22 work days

Many laminators have a minimum production requirement of 5 million square inches or at least three 48" wide by 3000' rolls. IMPAK will produce laminate structures to fit your specific needs, even if it's a single roll. IMPAK has always been known for its large selection of materials on the production floor ready for converting, with 53 different materials in one Southern California facility! These substrates can be tailored to your exact requirements; we will take your product components and/or challenges into consideration and create an entirely new film.

Some examples of our custom laminations:

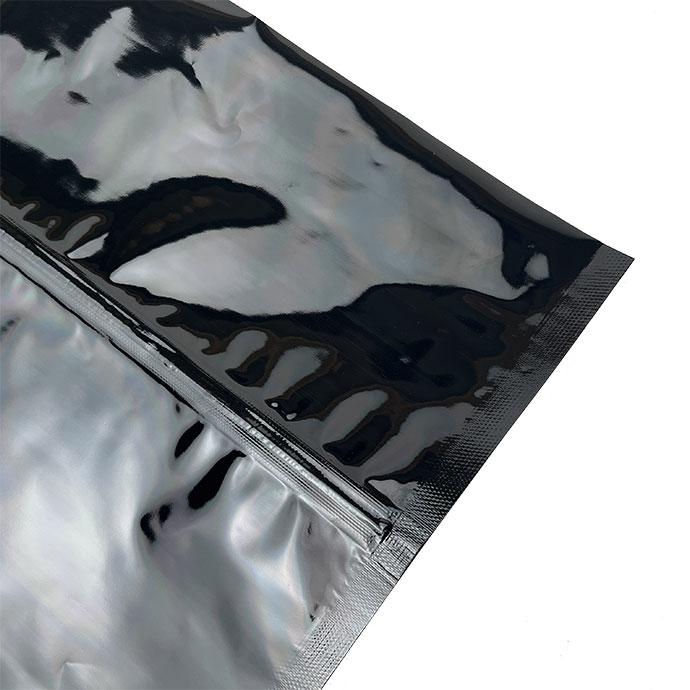

PAKVF4PC: This MylarFoil film was developed to handle essential oils and aggressive products that cause delamination in lesser structures. The proprietary sealant layer is also designed with minimal additives and stabilizers to eliminate outgassing, providing an inert contact layer for sensitive media.

PAKVF4C100: This MylarFoil film is known for its high hot tack strength, wide range of seal ability, and ability to seal through contaminates, such as fine powders (i.e., vitamin powders, protein powder, etc.). It also provides an excellent barrier for oily or greasy products. The incredible 1 mil thick foil layer virtually guarantees no pinholes!

PAKSAFE320: This MylarFoil film has excellent oxygen and moisture barrier properties and a sealant-layer temperature contact capability. The original application for the material was in high performance urethane adhesives being loaded into 5 gallon (23L) and 55 gallon (300L) containers where the material must be able to withstand 160° Celsius (320° F).

IMPAK has wide access to the materials to make these laminate structures and can accomodate a wide range of thickness requirements.

CASE STUDY 1

A major pharmaceutical manufacturer was in need of a material structure with a 75 gauge (19µm) PET layer, a .00063" (15µm) ALU layer, and a 4 mil (100µm) PE layer to hold a unique compound they were developing with exacting barrier requirements. As you can see by the metric measurements, this was an export product. IMPAK created our BarrierFlex™ material to fit their precise specifications. Laminating, converting, and shipment was completed in under 30 days.

BarrierFlex™, with foil and polyester layers much thicker than standard structures, has a higher moisture barrier than any other material offered by IMPAK (including PAKDRY7500). Currently we have two ready-to-ship pouches available in this material:

CASE STUDY 2

We were approached by another U.S. pharmaceutical company that was procuring their material overseas and had run into significant supply chain issues. Specifically, one of the elements of the film structure requested was difficult to obtain, challenging to work with, and rarely used in high-barrier flexible packaging.

IMPAK's packaging engineers were able to create pouches exactly to the customer's specification (provided in metric units - no problem for our team), producing pouches that easily met their high standards for being sterile, non-toxic, and providing a robust moisture barrier. LEARN MORE

If you are looking for information about laminate films sold by the roll, please see our pages on Rollstock or Tubing

If you are in need of a material made to your specifications, or if your current supplier is unable to meet your desired lead time, reach out to one of our Technical Representatives for a solution.