The History of Ziploc® Bags

How resealable pouches went from binder inserts, to sandwich bags, to the range of advanced solutions offered by IMPAK today.

It may be hard to believe for those of us who grew up using zipper bags, but these items were so novel at their introduction that people did not know how to open them. In fact, Steven Ausnit, the pioneer of Ziploc® brand bags (Ziploc® is a registered trademark of S. C. Johnson & Son, Inc.), recalled the struggle in introducing this product during a speech he gave at Marquette Business school. He recounted a time in the early 1960s when his company had just persuaded Columbia Records to package albums in the zippered bags, but during the final meeting, the executive from Columbia Records called in his assistant, handed her the bag and told her to open it. At which point, she tore the zipper right off the bag.

Consumers have long since figured out how to open zipper bags, but these products went through many transitions and over 100 patents to reach the advanced capabilities IMPAK offers today.

1950s: From Zippers with Teeth, to Plastic Slider Zippers

Prior to the 1950s, Ziploc® bags did not exist. In fact, zipper-style reclosable plastic bags had yet to be invented at all. (Ziploc® is the most well known brand of reclosable plastic bags, now owned and registered to S. C. Johnson & Son, Inc.)

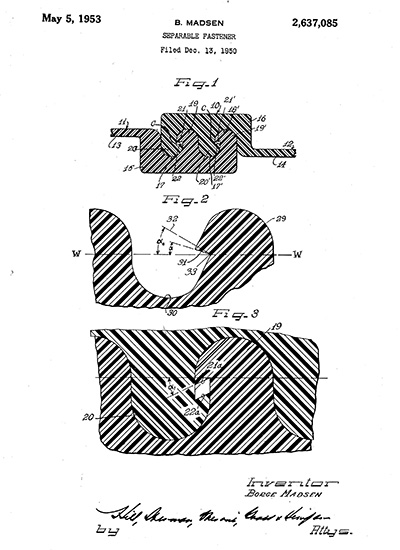

The press to close zipper bags we know today evolved from Danish inventor Borge Madsen’s attempt to create a new clothing zipper. Instead of teeth like we see on pants zippers, Madsen’s "separable fastener" design used interlocking plastic tracks and a slider tab. These zippers (pictured in Madsen’s original patent, right) were innovative but impractical for clothing. It was only once Max Ausnit and his son Steven Ausnit purchased Madsen’s patent that the zipper began to get traction as a consumer item.

The Ausnits formed Flexigrip Inc. in 1951 and began to sell the zippers applied to flat vinyl pencil cases and loose leaf binder inserts. While these products were a far cry from the zip lock pouches and other resealable bags we see in grocery stores, they were the early beginnings of these items.

* IMPAK offers a pull tab zipper bag reminiscent of this early design. This item is popular for disaster preparedness and marketing materials: PM4141251025 14.125” X 10.25” Clear Pull Tab Zipper Bag

1960s: Press to Close Convenience Arrives

During the 1960s Flexigrip began to move away from slider-style zippers following Steven Ausnit’s development of a press to close zipper. Not only was this new style more convenient to use, it also reduced material and production costs.

From an Industrial Supply, to a Household Staple

Reclosable zipper bags had gained interest but they were still expensive and complicated to make, mainly due to the fact that the zippers had to be heat sealed to the bags, which added time and cost.

This all changed when Steven Ausnit learned of a Japanese company, Seisan Nippon Sha, that had incorporated a zipper right into the bag. This cut production costs in half. In 1961, Flexigrip negotiated with Seisan to gain exclusive selling rights in the United States and created a new company called Minigrip to market this format.

Minigrip primarily sold to industrial markets until 1964 when they were approached by Dow Chemical for exclusive rights in the supermarket industry. Dow’s polyethylene resin bags were ideal for Minigrip’s reclosable plastic zippers. After several years of negotiation, the Ziploc® bag was introduced to the consumer market.

1970s to Today: ZipSeal Bags Find Their Market

Costly production coupled with challenges in understanding how to open the bag had stalled popularity, but by 1973 ziplock bags were a household staple. Dow Chemical had vastly improved the production process and lowered costs, and consumers had caught on. The Ziploc® bag dominated flexible packaging production and continues to do so today.

The Ziploc® brand is now owned by S.C. Johnson, producers of household brands including Glade®, Pledge®, Windex®, and Raid®. While S. C. Johnson’s Ziploc® brand produces reclosable polyethylene bags for consumers, ITW Corporation’s Zippak brand produces plastic zippers for industrial markets. In fact, the Ziploc® Brand does not produce industrial zippers for application to high-barrier materials and multi-layer films, and companies like IMPAK never use Ziploc zippers on their products. Learn more about IMPAK’s ability to pair innovative zippers with a range of materials that far exceed the capabilities of standard polyethelene sandwich bags below.

“Producers continue to innovate to deliver outstanding products to consumers” – Chad Rupert, President of ELPLAST* America and former Slide-Rite® Product Manager *ELPLAST America supplies press-to-close zipper products used for flexible packaging in the food, lawn and garden, pharmaceutical, and pet food industries.

The Future and Its Wide Range of Possibilities

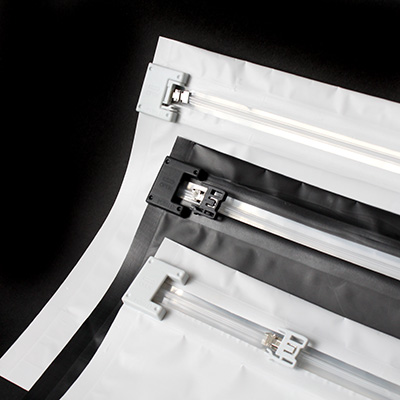

The zipper profiles available today deliver new functionality to reclosable bags, and IMPAK’s ability to pair these zippers with a range of high-performance materials brings that functionality to new dimensions. Zippers serve as a value-added feature that can expand a package’s appeal and function. IMPAK offers zipper profiles with unique features that suit industries including food, chemical, pharmaceutical, medical, adhesives, automotive, machinery, electronics, and aerospace.

Not Ziploc® - IMPAK produces all kinds of ZipSeal™ bags

There is a wide range of plastic zippers, including pouches just like the ziplock bags you know, and IMPAK can can make any kind you need. Our capabilities in flexible packaging are a testament to the evolution of the reclosable bags that started as binder inserts and became household items like sandwich bags. Our range of zipper profiles address packaging challenges that exceed the capabilities of a standard ziplock bag. These challenges include packaging liquids, fine powders, and aggressive chemicals. Select from stock zipper pouches measuring as small as 2” to as large as 28” or contact us to custom produce ZipSeal bags in a range of materials.

Beyond the Zipper: High Performance Materials

Some challenges are not solved by the type of zipper, but by the material that the zipper requires to mate with other custom laminations, a particular skillset of IMPAK.

For example, we offer pouches made from high temperature materials designed to safely cook contents inside the package, commonly used for packaging tuna and salmon. Many people do not realize it but these products are actually cooked for 55 minutes at over 230° Fahrenheit (110° Celsius). The challenge here for the flexible converter on a multi-use pouch was providing a material that would withstand that temperature and still maintain the water-tight seals. Unsurprisingly, the development of a package in which the product would be cooked in the bag required significant testing on extractables, and the ability to withstand autoclaving and not impart any component of the packaging material to the food product. IMPAK has this raw material readily available for conversion into pouches with and without ZipSeals™, and in fact stocks autoclavable bags as small as 2” x 3” and as large as 20” x 24.” See them here: Boilable / Microwavable Bags.

Boilable bags are just one of the advanced options available through IMPAK Corporation. With over 20 years’ experience in flexible packaging, and our background packaging sensitive medical devices and tests, we understand the discerning needs of industries from pharmaceutical and aerospace technology, to food packaging and preservation.

IMPAK's Zipper Guide: Zippers of Today

These zipper styles are readily available on regularly produced products; if not readily available, they can be used in conjunction with our pouch making machinery. We can run test and production quantities of almost any zipper profile in the marketplace. Learn more in our ZipSeal™ Guide below, or Contact IMPAK.

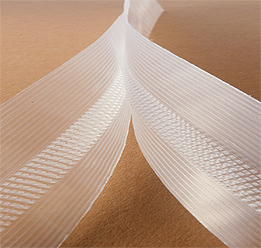

UniTrak™, Single Track Zippers: The majority of our pouches offer the standard ZipSeal, which is a single track zipper. This press to close zipper style employs a single piece of material which protrudes from the pouch and fits directly into a track on the opposing side of the pouch. Interlocking plastic pieces snap into place and create friction to prevent the zipper from opening. This is the most commonly used profile and it is applied to pouches from standard clear zipper bags to Mylar foil zipper bags.

To see regularly produced, ready-to-ship items with UniTrak™ zippers see our ZipSeal™ Pouches section. These pouches have single track style zippers unless otherwise noted.

Pocket Zippers: This zipper is concealed under a tear-away strip that serves as a tamper evident cover. Contents are filled from the top and sealed above the zipper so that the zipper is protected until being opened by the consumer.

Available by customer request and on this popular item:

6.0" X 2.875" X 8.25" Black Side Gusset Flat Bottom Pouch With Pull Zipper

4.0" x 7.0" x 2.5" O.D. PMS 2142C Stand Up Pouch - Square Bottom, Pocket Zipper, and Rounded Corners

TwinTrak™, Dual Track Zippers: Should you need something stronger, we offer a dual track ZipSeal™ with two slots and two tracks for added strength. These are commonly used on large bags or when package contents are highly valuable. This is an ideal profile because it minimizes the possibility of being opened unintentionally. The TwinTrack™ ZipSeal is also widely used in liquid/viscous applications where the pressure applied by the product might force a single track zipper open from the inside. Available on custom orders and on these popular items:

Croc-Lok™ Zippers: Arguably the most secure ZipSeal™ option, Croc-Lok™ zippers feature TripleTrak™ technology, with three tracks and slots for a seal that will hold under the most arduous use conditions. This style is desired for large pouches used to hold heavy weight contents, and is a great choice for keeping liquids safely contained in your package.

Available by customer request and on these popular items:

Child Resistant Zippers: IMPAK offers a range of Child Resistant ZipSeals™ which are designed to prevent children from opening the package while allowing adults with more dexterity to open them easily. These come in several profiles from slider tab and latch ZipSeals, to press to close zippers that are as easy to close as a sandwich bag, yet keep children out. * For accuracy IMPAK refrains from calling these child-proof zippers as other manufactures will.

Available by customer request and on these popular items:

PowderZip™, Powder Zippers: PowderZip™ zippers feature small channels in the zipper that allow any powder stuck in the track to simply drop back down into the bag before and during the process of sealing the bag shut. This allows for a strong and secure seal even when using materials that would otherwise clog the zipper and prevent a proper seal.

Available by customer request.

AquaGuard™, Liquid Zippers: Liquid-tight AquaGuard™ zippers have dual tracks on opposing sides and interior welded seals at each end to keep liquid and viscous contents inside without leaking, as standard zippers can be prone to doing. These are commonly used for consumable liquid packaging such as breast milk. The strong seal serves to keep contents in and contaminants out.

Available by customer request and on these popular items:

MultiUse™, Ultra Durable Zippers: These wide flange ZipSeals can be opened and closed repeatedly and are made to outlast standard zipper profiles which sometimes only last for as few as 10 openings (in the case of grocery store brand sandwich bags). We’ve tested these zippers and successfully opened and closed them over 100 times.

Available by customer request

Pull Tab Zippers: Pull tab zippers employ a hanging pull tab similar to the style used on clothing. These are reminiscent of the original ZipSeal bag.

Available by customer request and on this popular item:

Hook2Hook Zippers: The Hook2Hook™ closure system utilizes Velcro® technology and can be closed without lining up the two sides perfectly thanks to two wide tracks of plastic hooks that interlock when pressed closed. This zipper style makes an audible noise as it closes, assuring the user that has been securely closed. Hook-to-hook zippers not only take less pressure to close, they easily seal through powder and debris.

Contact us for more information on these zipper styles.

9.0" X 13.375" X 4.75" Silver Stand Up Pouch with Hook2Hook Zipper

Slider Zippers: Slider zippers are a convenient means of reclosing packaging. Consumers enjoy the ease and speed of sliding the bag shut, and the visual confirmation that their package is closed. Unlike press to close zippers, this zipper profile does not require alignment of the two sides; the pull tab directs the zipper tracks into place for a secure and easy close that can be used over and over. Contact us for more information on these zipper styles.

7.5" X 4.0" Clear Flat Currency Pouch with Slider Style Zipper

8.25" X 4.25" X 2.75" Clear Stand Up Pouch with Slider Style Zipper

9.75" X 4.5" X 2.375" Clear Stand Up Pouch with Slider Style Zipper

12.0" X 9.0" X 4.0" Clear Stand Up Pouch with Slider Style Zipper

9.0" X 13.375" X 4.75" Silver Stand Up Pouch with Slider Style Zipper

Our team can help determine the unique combination of material and zipper profile that would best suit your application.

IMPAK’s zip lock bag capabilities are not limited to the zipper profiles listed above. With over 10 million bags in inventory, we can most often supply a resealable bag that will work, but when a standard size will not meet the needs of our customer, or when a specific material is required, we can provide a custom order. Contact IMPAK for custom print, size, or material. Phone: (310) 715-6600, Email: flprocessing@impakcorporation.com

Visit more of our popular packaging categories: