How to Choose a Vacuum Sealer

IMPAK Corporation has decades of experience working with companies in diverse industries such as biomedical diagnostics, industrial manufacturing, aeronautical engineering, renewable energy systems, and international food distribution. We have developed specialized sealers for a range of applications, involving a wide variety of materials. In short, we have the expertise to help you determine the best vacuum packaging system for your product.

If this page doesn't answer your vacuum sealer questions, contact us to discuss possibilities.

The Basic Types of Vacuum Sealers

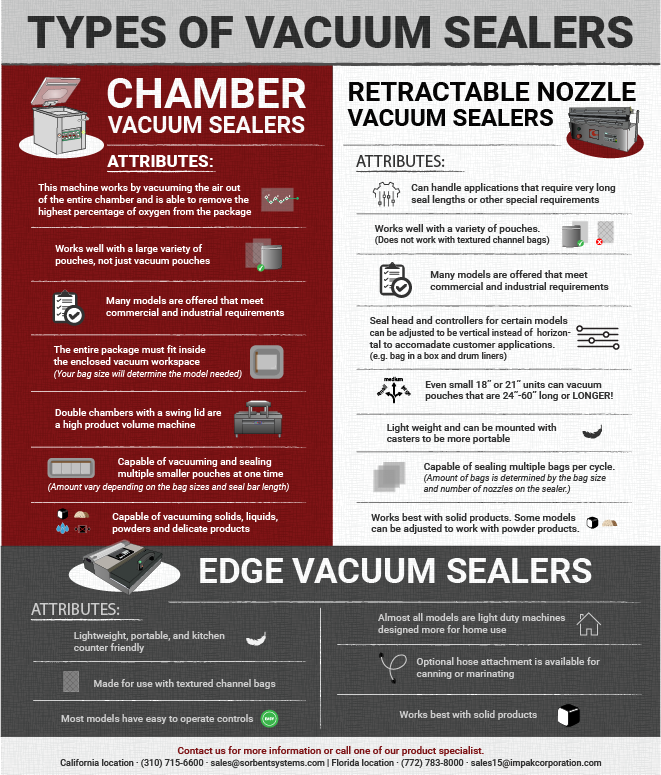

Chamber Vacuum Sealers

These are machines where all the vacuum and sealing of the package takes place within a fully enclosed work area. In most cases the package is placed within the enclosed work area the lid is then closed and the balance of the operation takes place automatically.

Learn more about how a chamber vacuum sealer worksRetractable Nozzle Vacuum Sealers

Like other external clamp vacuum sealers, these machines work by pulling air directly out of the vacuum pouch with no need for an enclosed work area. However, these units use a vacuum nozzle that protrudes into the pouch during the vacuum cycle and then automatically retracts from inside the pouch at the end of the cycle.

Edge or Clamp Vacuum Sealers

These machines are designed to work with pouches that have a textured surface. They have a small vacuum cavity located in the seal jaw area of the machine; when the jaw is clamped onto the textured bag, air is pulled through the channels or grooves on the bag. The most well known brand of this type of vacuum sealer is the FoodSaver™.

If you are interested in a sealer with no vacuum capability, explore or heat sealer options.

How to Evaluate and Choose the Best Type of Vacuum Packaging Machine

A decision has been made that your product needs to be vacuum packaged in order to prevent spoilage, oxidation, or some other adverse condition caused by oxygen left inside the package. The next step is to evaluate the vacuum packaging systems on the market and choose the type that best meets your specific needs. A small amount of research will show you that there are two major types of vacuum sealing machines on the market: chamber type units, where your entire package must be placed inside the vacuum cavity area of the machine, and non-chamber type machines that fall into two sub-categories. Non-chamber type vacuum sealers can be either nozzle type units or edge type (FoodSaver™) machines that require the use of special bags often referred to as channel or textured bags.

In the discussion below we will go through the pros and cons of each of these machines. For the purposes of this discussion, we will not be including several special types of vacuum packaging machines such as roll stock machines, vacuum skin packaging machines, and rotary chamber machines, all used for very high production vacuum packaging. If your product and application require these types of machines, please take the time to contact one of our vacuum packaging specialists to discuss your needs.

Chamber Type Vacuum Sealers

Chamber vacuum sealers are used for a wide variety of food and non-food products and are among the most versatile vacuum packaging systems available. A chamber vacuum sealer can remove more oxygen from a package than most other types of vacuum sealers on the market. Therefore, if your product is very sensitive to residual oxygen, a chamber unit would be the best choice for your application.

Chamber machines tend to be more operator-friendly as well, considering that once your package is placed properly inside the machine and the lid is closed, the balance of the cycle happens automatically. There is no need to manipulate the pouch to eliminate wrinkles in the seal area, which can cause leaks and ultimately, rejected packages.

Some users consider chamber units to be slower than non-chamber machines when sealing one package in each unit. However, if you are using smaller pouches, several can fit along the sealbar and be sealed in the same cycle. Many non-chamber units can only work with one package per cycle due to having a single nozzle. For units that have two nozzles, operators often find that placing pouches over each nozzle separately and lining them up properly for a quality seal is both time consuming and inconvenient.

Chamber type vacuum sealers are available in a variety of models from small tabletop machines to very large double chamber machines. Choosing the correct model for your application is dependent mostly on the size of your package and your throughput requirements. The videos available in the links below may help with that choice.

A typical cycle for a chamber vacuum sealer:

- The package would be placed inside the machine with the front of the pouch laying over the seal bar.

- The operator would then close the lid.

- The vacuum pump will engage.

- The vacuum potion of the cycle will continue until either the set vacuum time has expired or the pre-programed vacuum pressure has been achieved, depending on the control system used in your machine.

- Once the vacuum cycle is completed your machine may engage a gas flush cycle (if equipped with this option) or move to the seal cycle.

- Once the seal cycle is completed a dwell or cooling time will engage.

- When the dwell or cool time part of the cycle is completed the machine will engage the vent cycle and once the chamber cavity is vented the lid will open.

- Some applications require a seal cycle that is controlled by seal temperature rather than time. To achieve this, we recommend units equipped with the iS2 Control System.

iS2 Medically Validatable Chamber Vacuum Sealer

CHTC-420 Stainless Steel Chamber Vacuum Sealer

IMPAK Corporation Chamber Sealer Comparison

Large Custom Medically Validatable Chamber Vacuum Sealer

Nozzle Type Vacuum Sealers

Nozzle style vacuum sealers are the most commercial type of non-chamber vacuum sealers and are offered in a large variety of models with varying capabilities. Their common characteristic is a retractable nozzle for eliminating the atmosphere from inside a pouch. The nozzle is inserted into the bag close to the actual product to avoid the pouch material collapsing over the nozzle opening and preventing the pouch from being properly evacuated. Once the vacuum is complete, the nozzle is retracted behind the sealbar and the pouch is sealed.

Since this type of system draws the atmosphere directly out of the pouch instead of a vacuum cavity area, the pouch is drawn to the contours of the product inside, thus putting it under pressure right away. For most products, being under pressure from the collapsing pouch causes no issues, but in some cases, this pressure on the pouch can be extreme enough to cause wrinkles in the seal area. This must be avoided by either manual or mechanical means in order to limit rejected packages.

One important advantage of nozzle type machines is that the size of the package is only restricted by the length of the machine's seal bar - the length of the pouch is not a limiting factor. With chamber type vacuum sealers, the entire package must fit inside the vacuum cavity area. The larger the package, the larger (and more expensive) the chamber model must be to accommodate it.

Many nozzle type vacuum sealers require both a power source and a compressed air source. The compressed air is required to operate air cylinders that provide motive power to the seal jaws, nozzle retraction cylinders, and in many cases, the venturi system used to generate vacuum flow. However, there are now nozzle type machines that require only electrical power to operate. These models use electric motor systems to power the seal jaws and nozzle retraction cylinders, and to operate small electric pumps that supply the vacuum flow.

EVS All-Electric Vacuum Sealer from IMPAK

High Flow Vacuum Sealer (Medically Validatable)

PneuVak (PVS) Vacuum Sealer

Custom Gramatech GXVS 61" Validatable Vacuum Sealer with SIEMENS HMI

Edge or Clamp Type Vacuum Sealers (e.g. FoodSaver®)

The edge type vacuum sealers are machines that require the use of a special type of vacuum pouch often referred to as a channel bag or a mesh bag. This very fact eliminates their consideration for many packaging applications as these types of bags are not available in a large variety of materials. These types of pouches are also much more expensive than most regular, non-embossed vacuum pouches. This shortcoming, among others, means that this type of vacuum sealer is most often used as a home use machine to help preserve food from both spoilage and freezer burn, as well as a very limited number of commercial applications. The most relevant advantages to this type of vacuum seal are their low cost and ease of operation.

CounterMate Deluxe Home Vacuum Sealer for Channel Bags

CounterMate Pro XL Vacuum Sealer