How to Package Hops

Hops Packaging Guide

The Complete Package: High Barrier Bags, Oxygen Absorbers, Nitro-Flush Vacuum Sealers

Packaging hops for lasting freshness is best achieved with an opaque, high barrier package which has purged of oxygen either through vacuum sealing or an oxygen absorber packet. The best storage system will vary depending on whether you are at the farming or brewing stage.

How to Select the Right Package

The “right” package will depend on factors such as how long you will be storing the product, what volumes you are looking to store, and how the product will be handled next. Whether you are a farmer, craft brewer, or a home brewer, you want to make sure your package blocks light and oxygen, which are known to corrode your product. Most typically our hops customers are using MylarFoil films with food-safe inner layers, but we also see clear vacuum bags being used, particularly by home brewers who are pre-portioning pelletized hops to freeze. Read on for recommendations specific to your stage and process.

Removing Oxygen

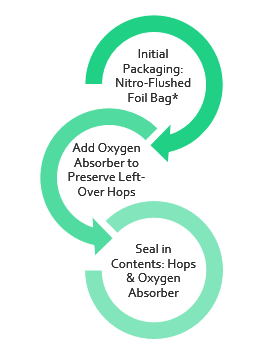

Preserving the freshness of your hops is about more than the proper bag selection. Your next step is creating a controlled low oxygen environment. For hop farmers at the initial packaging stage, we recommend a vacuum seal with a nitrogen flush. Later, once the bag has been opened by the craft brewer, we recommend a hand held sealer to close partially used bags. At this stage we also recommend an oxygen absorber to reduce oxygen levels for greater freshness. Home brewers looking for an inexpensive method often use home vacuum sealers in combination with textured channel bags, which they then freeze.

Why Does High Barrier Protection Matter?

Proper storage requires a controlled atmosphere. For over 30 years, IMPAK has provided customers with innovative packaging solutions, from flexible packaging products such as high barrier bags, to desiccants, oxygen absorbers, and sealing machinery. We know high barrier packaging and created the Hops Green line after noticing an increasing number of our vacuum bags / Mylar bags were being used to package hops. Select from 3 convenient sizes at a cost-effective price point.

Misconceptions About Preserving Hops

There is a lot of misinformation about food preservation and storing hops. Preserving hops comes down to the same principles as any other long term food storage: it’s all about the barrier, and keeping oxygen and other contaminates out. Whether you're packaging for a few days, or a few months, a controlled environment is critical to preserving freshness and flavor.

Vacuum sealed Mylar bags are the preferred choice for professionals, while home growers may opt for clear vacuum seal bags similar to FoodSaver® bags. IMPAK offers both. In addition to our Hops Green Bags line, IMPAK offers a wide range of Mylar foil pouches in silver and clear vacuum bags.

IMPAK does not claim to be experts on packaging hops. We leave that to professionals like Mark Garetz, author of Using Hops. *Using Hops was published in 1994, which means Mr. Garetz has been working with hops for at least as long as IMPAK has been working with high barrier packaging. He writes, “Vacuum packing and inert-gas packaging in an oxygen-barrier material are the best packaging methods. The common type of oxygen-barrier packaging is the "boiling bag" which is clear and made from a lamination of two types of plastic… The next step up in effectiveness is the aluminized mylar bag (also known as the foil bag or pouch), which adds a layer of aluminum that increases the barrier protection more than 10-fold." – Mark Garetz, Brewing Techniques

Hops Packaging for Hops Farms

Ensuring that your crop maintains the same great flavor and smell comes down to proper bag selection and the removal of oxygen. There are several methods and equipment options but your basic goal is to package your product quickly in a low oxygen environment.

Initial Packaging: How to Select the Right Package

A proper barrier against elements such as light and oxygen is the first step in maintaining product freshness. Typically hops farmers select a mutli-layer film composition with a food-safe inner layer. IMPAK’s PAKVF4C material takes this a step further with a sealant layer capable of sealing through the oils and powders that are typical in fresh hops packaging. Bags constructed of this material range in sizes from a few ounces to 11, 22, and 44 pounds and larger.

Ensuring Product Freshness: How to Remove Oxygen

Keeping hops fresh is a matter of removing oxygen. This can be achieved in 2 ways: vacuum sealing the bag after a nitrogen-flush; or sealing the bag with an oxygen absorber inside. For long term freshness you could combine all of the above, however most of our customers find that choosing one or the other is more than sufficient for the length of time they will be storing their product.

Hops farmers generally prefer a nitrogen-flush vacuum seal over oxygen absorbers because of its immediacy and convenience. Oxygen absorbers are often called “oxygen scavengers” because they scavenge residual oxygen; with a nitrogen-flush and vacuum seal you are removing most of the residual oxygen almost immediately.

Equipment

IMPAK's all-electric industrial vacuum sealers are outstanding units for medical and clean room use. Unlike air driven pneumatic sealing machines, The electric sealers have no need for an air compressor source. Since the sealers do not require an air compressor unit, these motor driven vacuum sealers will work more quietly than other pneumatic driven vacuum sealers on the market. This sealer gives a strong 5mm - almost .25 inch - seal from a frame that is built for either 17.7" or 13.8" wide pouches. See our stock units here: Electric Vacuum Sealers |

The PneuVak sealers are pneumatic vacuum sealers capable of handling a wide range of materials, with added controls for gas flush and safety features such as an emergency stop. These vacuum sealers have a small foot print (as small as 27” x 11” x 12”) and require only a power source and air source. See our stock units here: PneuVak Vacuum Sealers |

GVS - WorkHorse Vacuum Sealers This tabletop vacuum sealer machine is made from high-grade stainless steel and quality anodized aluminum frame. It's good for medium to high production use. It comes with dual heat elements, PLC touch screen, single-ported exhaust, stainless steel frame, Venturi vacuum pump, and twin retractable nozzles as standard features. Contact our team for custom units, and see our stock units here: WorkHorse Vacuum Sealers |

Custom Pak -Stand Mounted Vacuum Sealers This vacuum sealer machine with mobile stand and separate control head is made from high-grade stainless steel and quality anodized aluminum frame body. This retractable vacuum sealer comes with dual heat elements, PLC touch screen, single-ported exhaust, stainless steel frame, Venturi vacuum pump, and double retractable nozzles as standard features. See them here: Custom Pak Vacuum Sealers |

Large Barrier Bags

The sustainable, economic packaging option for growers and brewers.

These multi-layered bags are light-resistant, oxygen resistant, and have a special layer that will seal through oils and powders, which makes them ideal for hops packaging. They are produced in an FDA-approved, food grade material (PAKVF4C 5.0) in forest green, and are sized for 11lb., 22lb., and 44lb. pelletized hops (1lb., 5lb., and 10lb. fresh bale).* A multi-layered Mylar foil bag is your best bet for long term food storage and our hops bags may be vacuum sealed, nitrogen flushed, and reused. IMPAK also offers a wide range of oxygen absorbers and sealing equipment to complete your hops packing process. *Other packaging solutions include our standard MylarFoil bags, or Boilable Bags

*Weight varies by hops form, contact IMPAK for samples to test your product

Features & Advantages

- Nitro-flush ready

- Vacuum-seal ready

- Puncture resistant, food-grade material (PAKVF4C - 5.0mil)

- Superior barrier properties protect from light, oxygen, and moisture

- 3 standard sizes (see our Mylar bags page for more unique sizes)

- Sustainable & space saving for reduced shipping costs

- Reusable/ resealable: may be sealed again and paired with an oxygen absorber when contents are not used in one setting

- Material seals through oil & powders, without jeopardizing the heat seal (i.e. ketchup packets)

- Ready to pair with our sealers and oxygen absorbers

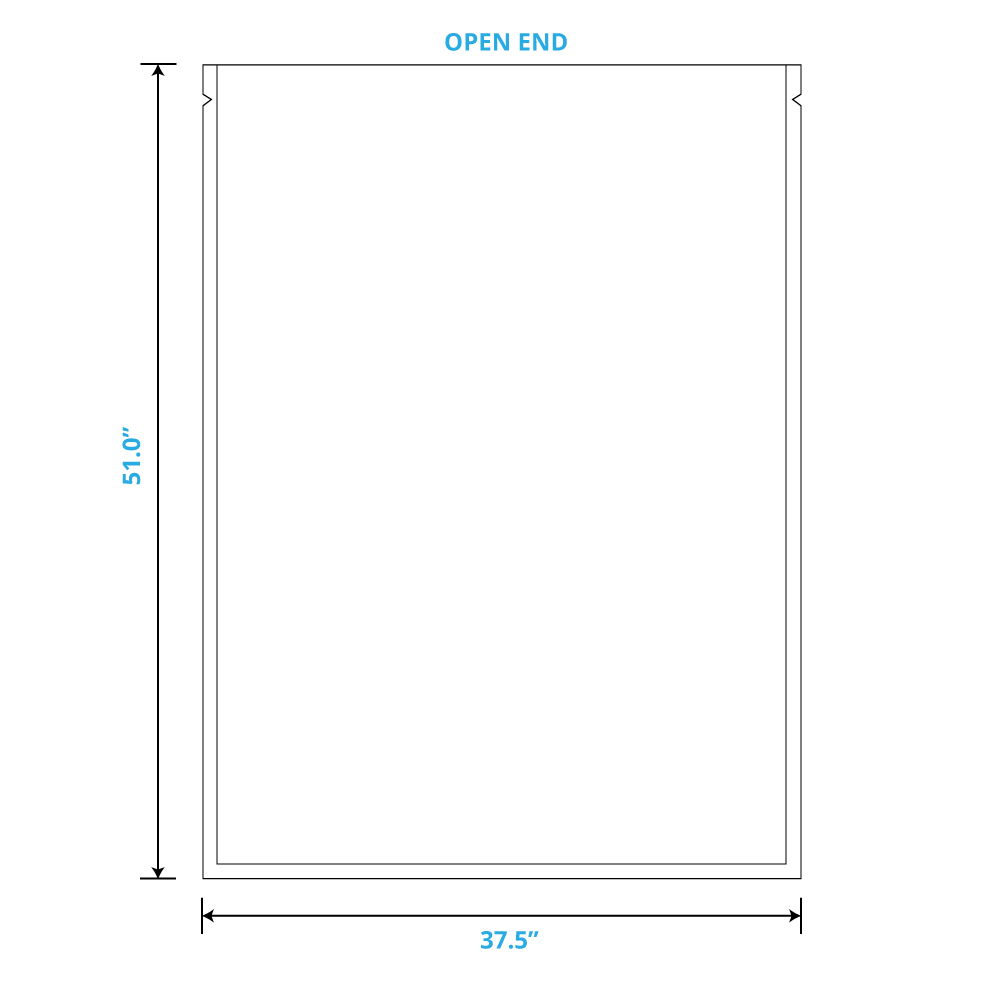

Bulk Processing "Leaf" Bags - 37.5" x 51.0" Flat High Barrier Bags

The same proprietary material used for IMPAK’s Green Hops Bags is used on these large high barrier bags for bulk processing of whole-leaf hops, or even pellets.

Although the bags are silver, not green, they have the same sealing layer which is capable of sealing directly through powders and oils. They can also be opened by cutting a portion off and then resealed afterwards.

Interested in the unique barrier properties of this material? See the Spec Sheet here: PACVF4C

Buy pouches here P/N: 375VF4C51

Custom Printed Pouches

For those who are retailing and/or wholesaling their hops to brewers and want a stand-out look, IMPAK offers full custom print services and even custom flexible materials. The attractive pouches shown here, produced for Yakima Valley Hops, are made from 50% post-consumer recycled material. That's a great way to help with waste reduction while still getting the reliably high oxygen and moisture barrier required for hops packaging. Contact us to discuss the unique branded packaging possibilities for your product.

Hops Packaging for Craft Breweries

Typically, we see that our craft brewers receive their pelletized hops from their hops supplier and are more concerned with resealing opened bags while maintaining freshness, and possibly re-packaging their hops in different volumes. IMPAK has solutions for these different needs.

Resealing Hops Bags

IMPAK offers several very simple solutions for resealing opened bags of hops. These range from bag clips that offer an air-tight seal without the need for a heat sealer, to hand held heat sealers such as our 6" HotJaw, or our more robust hand held sealers, the US-Made HHI-Series which are T-Clamp Sealers that come in the following lengths: 8", 12", 15", 18", and 26". Another US-Made option is the similar portable sealer, the GXS-Series which are Scissor Sealers. See these options below, and read on for why IMPAK recommends pairing all of these options with an oxygen absorber.

HotJaw Portable Sealers

Available Sizes: 6"

Keeping Resealed Bags Fresh

Each time your bag is opened oxygen enters the bag and starts to deteriorate your product. To help fight the corrosive effects of oxygen, we recommend an oxygen absorber. This is a quick and efficient way to protect your product without slowing your process down. IMPAK has several oxygen absorber packet recommendations based on bag sizes below, but the appropriate size for you will depend on the frequency which you open your bag and the length of storage. We try and err on the side of over-production.

- 1000cc Oxygen Absorber, recommended size for 11 lb. Hops Bag

- 2000cc Oxygen Absorber, recommended size for 22 lb. Hops Bag

- 3000cc Oxygen Absorber, recommended size for 44 lb. Hops Bag

Re-Portioning Your Hops into Smaller Bags

Many of our craft brewer customers repackage their hops into the exact volumes they use in their production batches. For this they use any number of our flat and stand up Mylar-foil bags. For 1 lb. pellet bags we have several recommendations below, but we suggest browsing our entire Mylar category for other sizes. It is worth noting that IMPAK offers samples of our bags so that customers can test capacity of their specific product. The suggestions below are estimates and we recommend testing before placing a bulk order.

4.25" x 6.0" - Green MylarFoil Flat Pouch with Tear Notches (P/N: 0425VF4C06GR)

8.0" x 10.0" - Green MylarFoil Flat Pouch with Tear Notches (P/N: 08P4C10GRRC)

6.0" x 9.37" x 3.25" - Kraft MylarFoil Stand Up Pouch with Zipper & Tear Notches (P/N: CLK325Z)

6.0" x 9.375" x 3.25" - Black MylarFoil Stand Up Pouch with Zipper, Round Corners & Tear Notches (P/N: CBB325ZRC)

10.0" x 16.0" O.D. - Silver MylarFoil Flat Pouch (P/N: 10VF4C16RC)

10.0" x 16.0" O.D. - Green MylarFoil Flat Pouch (P/N: 10VF4C16GRRC)

Hops Packaging for Home Brewers

As the popularity of home brewing has steadily increased, we have seen the demand for packaging increase as well. Every home brewer seems to follow their own method, but we can share some of the common things we see. Most often we see home brewers repackaging their pellet hops into smaller portions which they vacuum seal in channel bags and then freeze.

IMPAK sells a wide range of pre-sized vacuum bags, as well as rolls that can be cut to size. One of our most in-demand sizes are our 4.0" x 6.0" vacuum bags which are used to package hops into 2oz portions. These bags are sold in a smaller case than our typical industrial quantities at just 100 bags. These bags are an excellent alternative to the cost and time of creating bags from FoodSaver rolls.

Home Brewer Special: 2oz Pellet Hops Vacuum Bags - 100 Pack of 4" x 6" Bags

4" x 6" textured vacuum bag 100 Pack (100 bags), ideal for 2oz hops pellet samples for home brewing.

Label says 2-4oz. hops pellets but with most commercial hops pellets, these bags will fit a max of 3.5oz. Request samples to test.

*Please note: labels on bags are for photo purposes only, bags come unlabeled

P/N: SSV50406-100pk Buy Here

| Size (OD) | Part Number | Material | Case Qty |

|---|---|---|---|

| 4"x6" | SSV50406 | 5 mil | 1000 |

| 6"x12" | SSV4R0612 | 4 mil | 1000 |

| 8"x12" | SSV4R0812 | 4 mil | 500 |

| 10"x14" | CH1014 | 3.5 mil | 300 |

| 10"x14" | SSV4R1014 | 4 mil | 500 |

| 11"x24" | SNS350 | 5 mil | 400 |

| 12"x16" | SS1216 | 3.5 mil | 500 |

| 15"x20" | SNS550 | 5 mil | 400 |

| 16"x26" | CH1626 | 4 mil | 200 |

Vacuum Sealers for Channel Bags

The CounterMate® Vacuum Sealers are an ecomomic option for home brewers looking to vacuum seal their hops with professional results. There are five models that range from $59.99 for the “Starter” series to $299.00 for the “Pro” series.

See them all here: CounterMate® Vacuum Sealers