Side Gusset Bag Styles

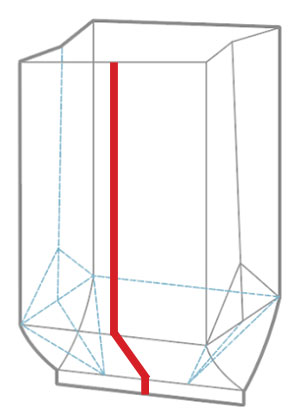

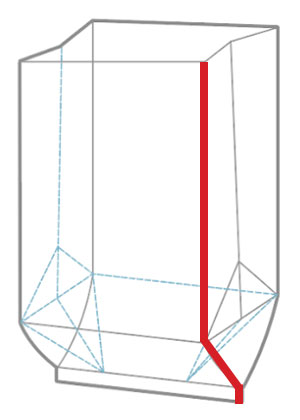

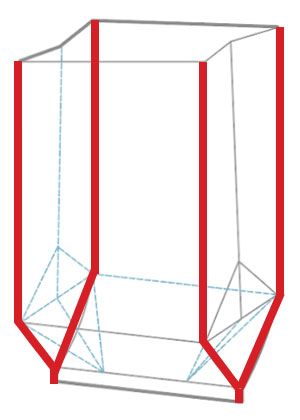

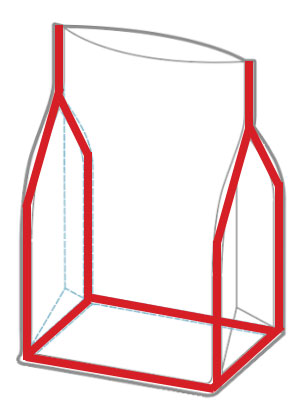

Side gusset styles (L-R): center seal, corner seal, quad seal, 8 side seal

Not long after basic 3-side-seal Mylar® bags started to replace rigid packaging in the latter half of the 20th century, producers saw an opportunity to expand the capabilities of flexible packaging. Simple flat pouches had limited capacity and were not well-suited for display purposes on retail shelves. Starting in the 1960s, gussets (sections of folded material) were incorporated into Mylar® bags to give flat pouches three-dimensional volume and allow them to stand upright on their own.

The two new styles that started appearing on shelves were the Doypack (the original name for what are now generally called Stand Up Pouches - read more about those here) and the Side Gusset Pouch, often referred to as the coffee bag due to its eventual popularity for coffee packaging. The main difference between these styles is that Doypacks have a gusset on the bottom of the pouch, as opposed to the aptly-named side gusset bags. Because of that design difference, side gusset bags tend to have a greater capacity/volume than stand up bags of similar dimensions.

Types of Side Gusset Bags

Side gusset bags can be fabricated in several different ways, all relating to the number and placement of seals in the material that makes the pouch.

Center Seal

The traditional coffee bag was made with a single web of material such that the seal appeared on the center of the back side of the pouch, similar to a fin seal pouch often seen with chip bags. One drawback to this style is that the center seal on the back side was challenging to work with when creating printed packaging. Designers had to plan text and graphics around that center seam. Nonetheless, this style of pouch is still widely used, often with one-way valves for degassing roasted coffee.

Corner Seal

To resolve the issue of designing around a center seal on the back side, some producers began making side gusset bags with the seal moved to a corner of the pouch. This allowed more flexibility for print designs, allowing full use of the back side of the pouch. However, the lack of well-defined "sides" on thes pouches still made it challenging to create a print design for a single piece of material that would align properly and consistently when the pouches were produced.

Quad Seal

In order to get more fine control over custom printing, the Quad Seal style was created. These bags are formed from two separate rolls of material, one for the front/back and one for the sides. This makes it possible to create more specialized designs, such as turning the sides of the bag into clear windows. The seals on all four corners help to define the shape of the bag more cleanly and firmly. Print designs are more reliably rendered and the bags feel more robust. This style is often used for larger pouches and heavier contents.

Eight Side Seal

Early styles of side gusset bags don't “stand up” with the same stability of a Doypack. The bottom only takes shape when the bag is filled, with the sealed material folded on the bottom making them slightly unstable when standing. The square bottom (or block bottom, box bottom, flat bottom, or 8 side seal) pouch is akin to the quad seal pouch but with an additional panel on the bottom, sealed on four sides. This type of pouch provides superior print design options (including print on the flat bottom of the bag) and stands up more securely than Doypacks, but it is also a more difficult and costly style to create.

IMPAK has produced all of these styles of side gusset bags for customers, often with added features like one-way valves, clear windows, ZipSeal™ closures, and tin ties. We are particularly proud of our capabilities in creating large side gusset bags for agricultural products, construction materials, powdered nutritional products, and more. Contact us to discuss how IMPAK can create the ideal side gusset bag for your product.