This machine REQUIRES an external air source with 80-100 PSI

to operate

Please note that 51" and 61" units need a 220V connection and cannot be modified down to 110V.

This tabletop vacuum sealer is made from high-grade 304 stainless steel and an aniodized aluminum frame. It's perfect for medium to high production use and comes with dual 0.25" heating elements, Unitronics color touch screen, single-ported exhaust, Venturi vacuum pump, and dual retractable nozzles as standard features.

Note: This unit requires a separate compressed air source capable of providing 80 PSI of clean, dry air.

Specifications:

- Model Number: GXVS-61TS

- Max. Seal Length: 61"

- Standard Seal Width: 0.25"

- Electrical: 220 VAC

- Vacuum Pressure: 25" Hg

Features:

- Dual Retractable Nozzles with High-Vacuum Flow Rate

- Upper and Lower 0.25" Heating Elements

- Unitronics V350 Color Touch Screen with 30 recipe memory

- Up to 9-stage gas flush

- Venturi Vacuum Pump

- Pneumatic Safety-System: Prevents accidental operator injury by use of a back-pressure sensitive micro switch to prevent jaws from locking down in the event an unwanted object (i.e. hand or finger) is present in the seal area.

- High-Grade Stainless Steel Body, Heavy Duty Anodized Aluminum Frame

- Illuminated on/off switch

- Emergency stop button on machine face

- Handles for portability

- Requires External Air Supply (80 PSI clean, dry air)

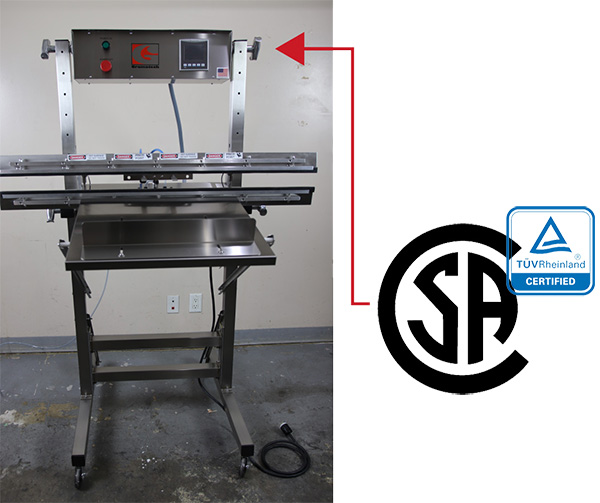

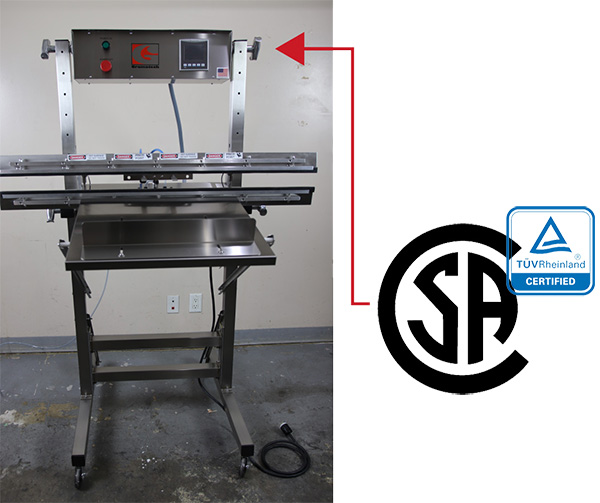

CSA Certification Announcement

IMPAK is proud to partner with a major Multi-National Pharmaceutical Company and to have been granted a CSA Certification for its industry leading line of Gramatech Vacuum Heat Sealers. “We are now ready to offer CSA registration as an option to our industry leading line of Gramatech Sealers,” according to Rajib Hasan, Managing Director, Machine Group.

As the company General Manager has said, “We are very proud of the machinery we have built to CSA standards.” The story below written by Alan Masnek, our resident Certified Packaging Professional (CPPL) and graduate of University of Wisconsin – Stout, illustrates the steps that were taken to design, develop and produce a piece of equipment for pharma MNC. This particular MNC is just one of the many top medical manufacturing firms we are proud to have produced product for. [see full article.]

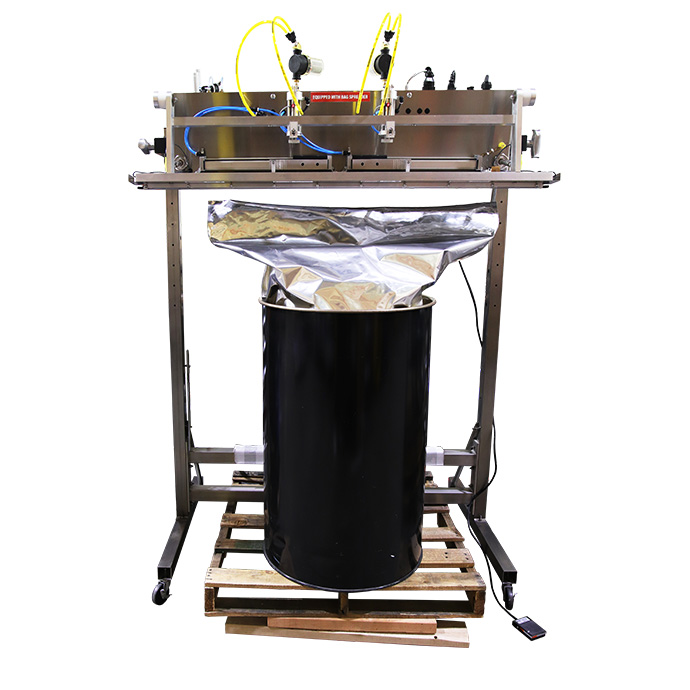

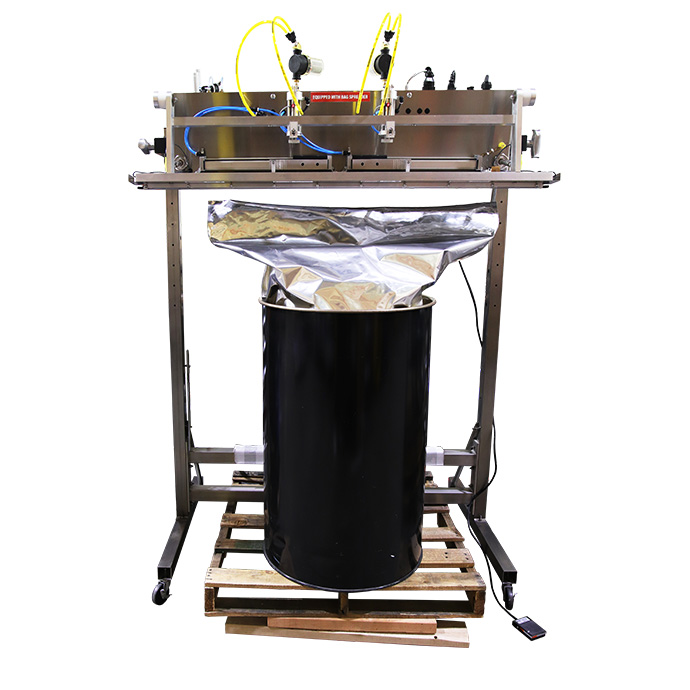

The GXVS CustomPAK family of vacuum sealers is perfect for sealing drum liners. The adjustable height and pivoting seal head provide a great amount of flexibility to fit your production line.

Stainless Steel Stand

All Stainless Steel means easy to clean, durable and able to perform year after year in almost any packaging environment.

User can adjust stand height from 42”, 45”, and 48” to accommodate user’s needs.

Clean Room Ready

Machine taken into Class 100 clean room where all surfaces are wiped down with an 80/20 mix of sterile water/isopropyl alcohol then double bagged and sealed in virgin poly bags.

3rd Party Certification

3rd Party Certification is provided independent company who calibrates the unit for time, temperature, and pressure. Upon completion a certification label with date is applied to the unit and PM/re-certification is generally done yearly.

0.375" Seal Width Upgrade

This upgrade changes out the standard 0.25" elements up to a full 0.375" each for a wider and more visual seal.

iS2 System Upgrade

The iS2 (Intelligent Sealing System) is a control system for heat sealing equipment that offers pin-point digital control over time, temperature, and pressure, via touch screen interface.

The system is more than a digital control upgrade, it combines an advanced Siemens PLC and HMI with proprietary pneumatic and electrical components, to deliver temperature control within one degree, accurate sealing time with readings every millisecond. Additional conveniences such as recipe storage, operator locks, and graphs of time/temperature put iS2 enabled sealers in a class of their own. Validation ports allow the user to confirm all parameters from a 3rd party calibration/certification service and data is available to be sent to a dedicated terminal to track and record all seals made by the unit.

10 CFM

Increases CFM from 7.8 to 10 CFM by installing an additional Venturi to the vacuum nozzle assembly.

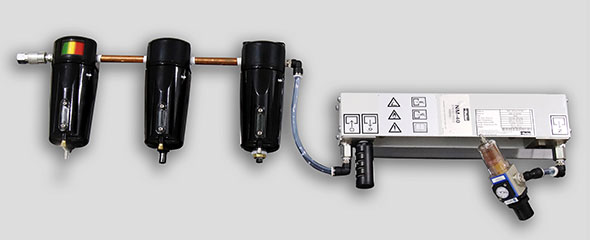

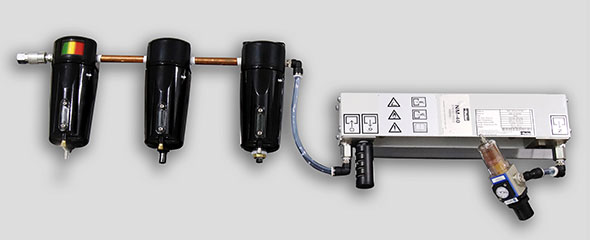

Sterile Air

Two Pre-filters with PM indicators which remove contaminants and water from the compressed air line before they reach the nitrogen generator. After leaving the generator the air is pushed through a Post filter which results in a Sterile Nitrogen flow of 99.9999+% efficiency at 0.01 micron. This is essential for food and sensitive applications where purity is critical.

Nitrogen Generator Kit

The Nitrogen generator produces Nitrogen gas (N2) from a standard compressed air line. This model is designed to generate Nitrogen at purities between 95% and 99.5%.

The Nitrogen generator can be used as a replacement for heavy and bulky Nitrogen gas tanks. Its slick and compact design allows users to integrate this with their current gas flush enabled vacuum sealers without having to worry about it taking up too much space. Also, users will not have to worry about a depleting Nitrogen gas source, as our generator produces Nitrogen from a clean compressed air source.

Sterile Air Kit with Nitrogen Generator

Part Number: GK-GVS61

Spare Parts Kit for 61" Workhorse

Includes:

- 2 - Teflon Insulators

- 6 - Teflon Covers

- 2 - Nichrome Elements

- 4 - Terminal Blocks

- 2 - Black Vacuum Rubber

- 1 - Orange Seal Rubber

- 1 - 5/32 Allen Wrench

- 1 - 1/8 Allen Wrench

- 1 - 1/16 Allen Wrench

- 1 - Flat-Stubby Screwdriver

Buy Here

GXVS-21TS : 21" Dual Retractable Nozzle Vacuum Sealer

GXVS-26TS : 26" Dual Retractable Nozzle Vacuum Sealer

GXVS-31TS : 31" Dual Retractable Nozzle Vacuum Sealer

GXVS-36TS : 36" Dual Retractable Nozzle Vacuum Sealer

GXVS-51TS : 51" Dual Retractable Nozzle Vacuum Sealer

View ALL Vacuum Sealers