iS2 - Intelligent Sealing System

An Advanced Control System for Heat and Vacuum Sealers

The iS2 (Intelligent Sealing System) is a platform that utilizes an advanced Siemens PLC, Siemens HMI, and proprietary pneumatic and electrical components to produce heat/vacuum seal solutions.

The iS2 System delivers precise controls of time, temperature, and pressure, with options to store seal recipes for repeated use. Originally developed to answer the need for validation in medical pouch sealers, the iS2 platform quickly expanded beyond tabletop units as we introduced customers to the range of controls available with such a system.

"[We are] glad we upgraded the sealers on our line with IMPAK's iS2 control system... it has delivered substantial savings on our production time and costs.”

– Manufacturing Engineer, U.S.-based Pharmaceutical Device Producer

IMPAK is capable of retrofitting this system on the equipment it builds, as well as competitors' thermal impulse heat, constant heat, or vacuum sealing systems.

How does accurate control of temperature, time, and pressure save time and money?

- Little to no parts changeover

- Reduce/eliminate production downtime

- No spare parts - save $$$ on SPKs

For most machinery manufacturing companies, spare parts kits are the life blood of the business, but not at IMPAK.

Multiple iS2 sealers being calibrated at once

Available iS2 Interfaces

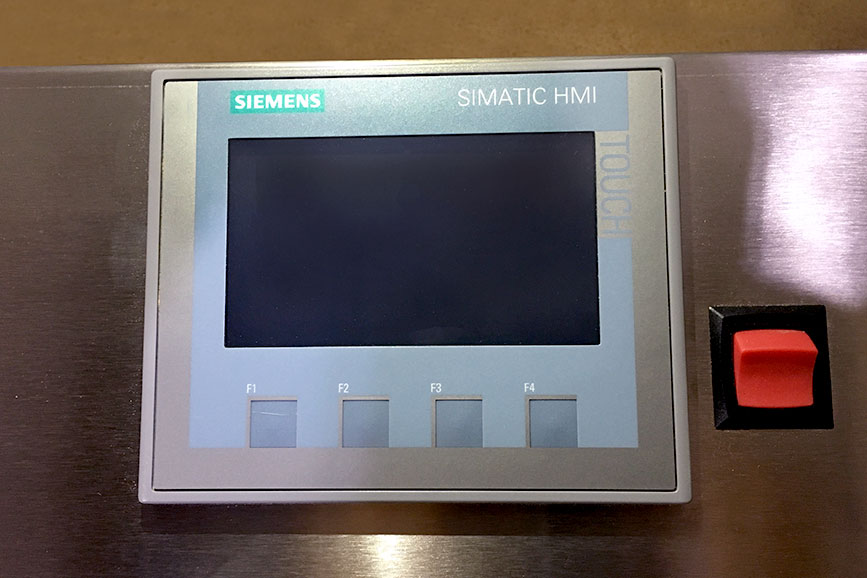

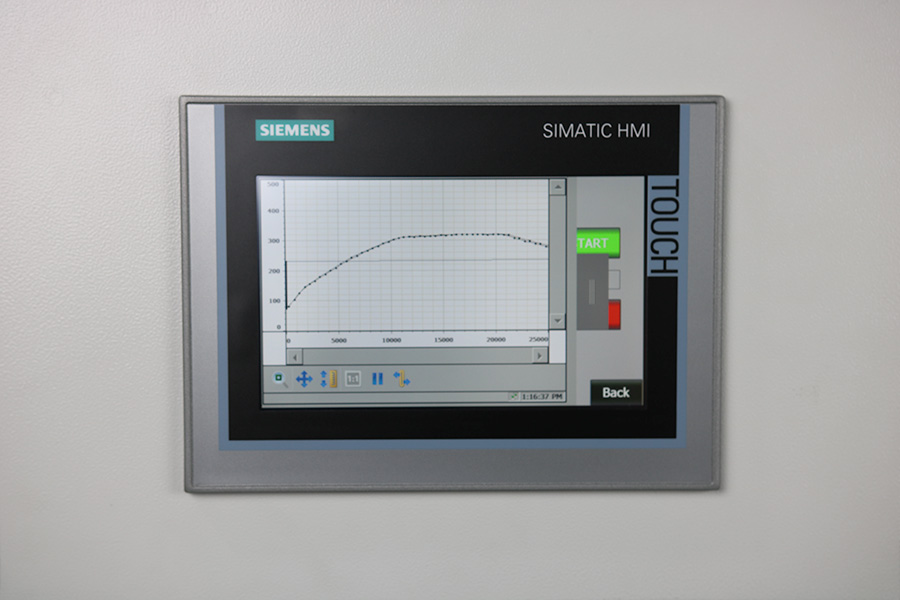

IMPAK currently uses three different Siemens HMIs with the iS2 System. The HMI used is determined by the size of the machine; tabletop machines utilize the smaller touchpad HMI, whereas large frame machines utilize the touchscreen HMI.

INTERFACE 1

Standard Touchpad

Our most used HMI for the iS2 System. Compact and compatible with small tabletop units. Stores one recipe.

INTERFACE 2

Touchscreen

This mid-size HMI is a slight upgrade from the standard touchpad with fewer keys and more recipe storage; stores up to 100 recipes.

INTERFACE 3

Advanced Touchscreen

A convenient 7" touchscreen HMI, compatible with large frame machines. Graphs time/temperature. Stores 500 recipes.

"IMPAK’s iS2 (Intelligent Sealing System) is a platform that utilizes an advanced Siemens PLC, Siemens HMI, and proprietary pneumatic and electrical components to produce heat/vacuum seal solutions. The ports and features it provides that make the calibration easy and efficient. Over the years, IMPAK has invested resources in developing features and technologies to advance its heat and vacuum sealers."

- Johnathan Brown, PME Services, Inc.

IS2 Machines: Easy to Calibrate and Validate (Watch video below)

Benefits of an iS2 System

Convenient Control - Advanced Siemens HMIs with Settings, Auto and Manual Test Menus. Touchpad or Touchscreen operation.

Temperature Accuracy - For legal reasons we claim “±3” degree temperature accuracy, but most tests show the accuracy of ±1 degrees F. The system takes temperature readings every 1-2ms.

Pressure Accuracy - Pressure control with 0.1PSI consistency and high tech proportional valve. Control high and low pressure from the HMI.

Time Accuracy - Adjust seal time in 1/10 second increments directly from the HMI.

Independent Thermocouples - Set independent thermocouple temperatures directly from the HMI.

Recipe / Formula Storage - A recipe is defined as the precise formula for temperature, pressure, and sealing parameters required for a specific material and application. Some companies in the industry refer to this formula as a recipe. We're uncomfortable with the term recipe used in this application since it implies vagueness, e.g., terms similar to 'pinch of salt' and a 'dash of vinegar' would not be acceptable. Since it is our nature to be specific and accurate for delivering technical solutions at IMPAK Corp, we refer to them as formulas. Wouldn't you rather be able to set your seal heat temperature at 243.7 deg F (117.61 C)?

| Touchpad | Touchscreen | Advanced Touchscreen |

|

|---|---|---|---|

| CPU | CPU 212 | CPU 215 | CPU 215 |

| Number of Recipes | 5 | 100 | 500 |

| USB Port | 0 | 1 | 2 |

| Pneumetic Proportional Valve | x | x | x |

| Temperature Control Module | x | x | x |

| Temperature Accuracy within ±3° F | x | x | x |

| Vacuum Sensor | x | x | |

| Trend of Graph | x |

Case Study: Upgrading to an Intelligent Sealing System Platform

Challenge: IMPAK was contacted by a large firm that manufactures plastic films with a challenge; upgrade a hand held heat sealer with old technology TIC (temperature impulse controller) and timer so that precise heat and cool temps can be measured and monitored. The heat sealer is used in their QC Lab and research and design lab to construct and test prototypes. [see full article]

Challenge: IMPAK was contacted by a large firm that manufactures plastic films with a challenge; upgrade a hand held heat sealer with old technology TIC (temperature impulse controller) and timer so that precise heat and cool temps can be measured and monitored. The heat sealer is used in their QC Lab and research and design lab to construct and test prototypes. [see full article]

Compatible Sealers

IMPAK can make any size table top (15", 20", 25" 31.5", 36", 51", 61") and industrial (36", 48", 60", 72", 84", 86", 96", 110", 210" and more) heat/vacuum heat sealer with this platform.

Videos of iS2 Enabled Machines

IMPAK has created validatable versions of many of our stock equipment. See just a few examples in the videos below.